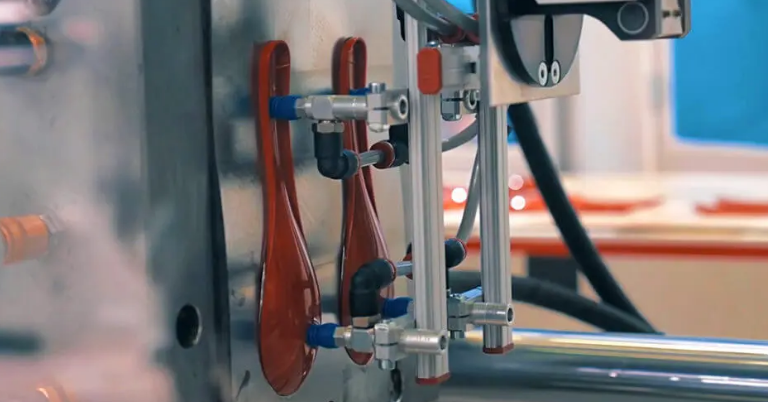

Injection molding can be cost-effective for mass production due to low per-unit costs but may require expensive tooling upfro

Understanding the Cost Structure of Injection Molding

Initial Investment and Setup Costs

Injection molding requires a significant initial investment, mainly due to the cost of machinery and mold design. Key elements include:

Machinery Cost: Prices vary, but a standard injection molding machine can cost from $25,000 to over $100,000.

Mold Cost: Custom mold designs can range from a few thousand dollars to tens of thousands, depending on complexity.

Facility Requirements: Additional costs for appropriate space and utilities to operate the machinery.

Cost Considerations:

Machine Size and Complexity: Larger, more complex machines increase initial costs.

Mold Design: More intricate designs lead to higher mold production costs.

Material Costs in Injection Molding

Material cost is a recurring expense in injection molding, influenced by the type and quantity of plastic used. Important aspects are:

Type of Plastic: Common plastics like polyethylene are more affordable, while specialized materials like polycarbonate are costlier.

Quantity of Material: Bulk purchases often reduce material cost per unit.

Material Cost Dynamics:

Market Fluctuations: Prices of plastic materials can vary based on market conditions.

Waste Management: Efficient material use and recycling can help reduce overall material costs.

For more in-depth information, refer to Injection Molding on Wikipedia.

Efficiency and Production Volume Impact on Cost

Cost Benefits in High-Volume Production

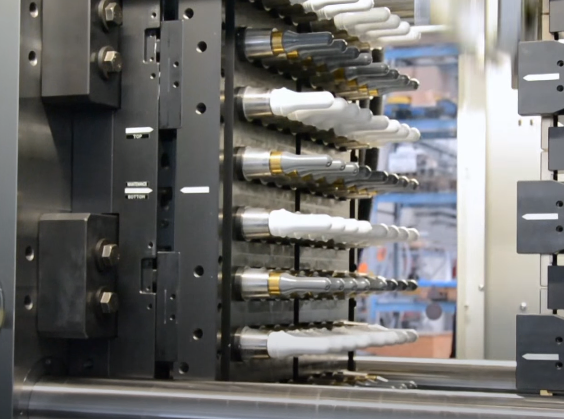

Injection molding becomes increasingly cost-effective with higher production volumes. This is due to several factors:

Economies of Scale: Large-scale production reduces the cost per unit. Producing thousands or millions of units can significantly lower the individual cost.

Reduced Labor Costs: Automation in injection molding means labor costs per unit decrease as volume increases.

Mold Amortization: The initial cost of the mold spreads over more units, reducing the mold cost per part.

Financial Impact:

Break-even Point: High-volume production helps reach the break-even point faster.

Long-term Savings: Consistent production over time maximizes the return on initial investment.

Efficiency and Its Effect on Overall Costs

The efficiency of the injection molding process plays a crucial role in controlling costs. Key elements include:

Cycle Time: Shorter cycle times mean more parts produced per hour, enhancing cost efficiency.

Energy Consumption: Modern injection molding machines are designed for energy efficiency, reducing operational costs.

Waste Reduction: Efficient use of materials and recycling of excess plastic minimize waste-related expenses.

Operational Considerations:

Machine Maintenance: Regular maintenance ensures optimal efficiency and prevents costly downtime.

Process Optimization: Continual process improvements can lead to cost savings and increased production efficiency.

For further details, visit Injection Molding on Wikipedia.

Comparison of Injection Molding with Other Manufacturing Processes

Cost Analysis: Injection Molding vs. Alternative Methods

A comparative analysis of the costs involved in injection molding versus other manufacturing methods like 3D printing, blow molding, and CNC machining helps to understand its financial implications.

Comparison Table:

| Manufacturing Process | Initial Cost | Production Cost (per unit) | Efficiency | Best Used For |

|---|---|---|---|---|

| Injection Molding | High (Machine and Mold) | Low (Mass Production) | High (Fast Cycle Time) | Large Volume Production of Plastic Parts |

| 3D Printing | Moderate (Printer Cost) | Moderate-High | Moderate (Slower Process) | Prototyping and Complex Geometries |

| Blow Molding | Moderate-High | Low-Moderate | Moderate (Depends on Complexity) | Hollow Parts like Bottles |

| CNC Machining | Moderate (Machine Cost) | High (Material & Labor) | High (Flexible Materials) | Metal Parts and Low-Volume Production |

Time and Resource Utilization Comparison

Time efficiency and resource utilization are crucial factors in manufacturing. Injection molding often stands out in these aspects when compared to other methods.

Comparison Table:

| Manufacturing Process | Cycle Time | Material Efficiency | Labor Requirement |

|---|---|---|---|

| Injection Molding | Short (Seconds to Minutes) | High | Low (Highly Automated) |

| 3D Printing | Long (Hours to Days) | Moderate | Low-Moderate |

| Blow Molding | Moderate | Moderate | Moderate |

| CNC Machining | Varies (Minutes to Hours) | Low (Material Waste) | High |

For additional information, refer to Injection Molding on Wikipedia.

Factors Influencing the Cost-Effectiveness of Injection Molding

Design Complexity and Its Impact on Costs

Design complexity in injection molding significantly affects costs. For instance:

Mold Design: A complex mold can be 15% to 30% more expensive than a standard mold. Reducing complexity might save 10% to 20% on mold production.

Cycle Time: Designs with intricate details may extend cycle times by up to 20%, impacting production throughput.

Testing and Rework: Complex parts could require 10% to 25% additional investment in testing and rework.

Balancing complexity with functionality is crucial; a 5% increase in complexity could lead to a 10% boost in functionality but at a 15% higher cost.

Material Selection and Cost Implications

Material choice plays a pivotal role in cost and quality. For example:

Material Costs: Common plastics like polyethylene are priced around $1 to $2 per pound, whereas specialized plastics like PEEK range between $10 and $15 per pound.

Impact on Costs: Using high-strength or high-temperature materials can increase costs by 20% to 50%.

Efficiency: For a 100-gram part, a $1 per pound difference in material cost leads to a $0.02 change per part. Optimizing material use can reduce waste and cut costs by up to 15%.

Considering recycled materials can offer 5% to 10% savings but may impact quality.

Delve deeper into this topic on Injection Molding on Wikipedia.