No, injection molding can be used for metals, ceramics, and other materials, not just plastics.

Understanding Injection Molding

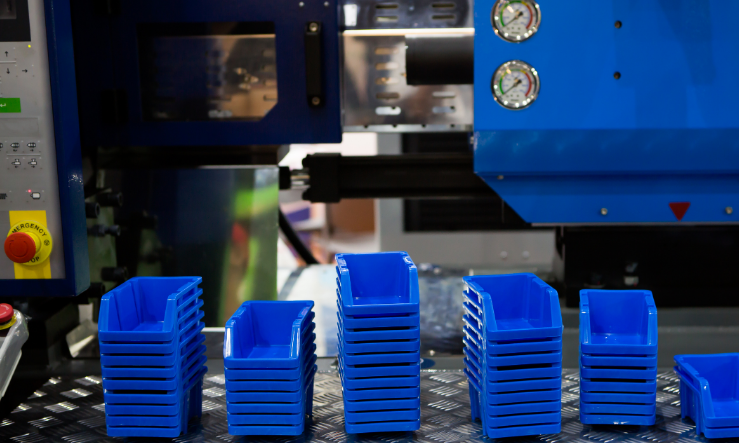

Injection molding stands as a highly efficient and widespread manufacturing technique, ideal for producing a vast array of items from tiny components to large car body panels. Its efficiency, precision, and ability to mass-produce identical items quickly make it a cornerstone in manufacturing.

Basic Principles of Injection Molding

Process Overview: In injection molding, manufacturers heat a material, usually plastic, to a liquid state and then inject it into a mold. The material cools and solidifies in the mold, taking its shape. This method excels in speed and accuracy, perfect for large-scale production.

Key Parameters:

Power Consumption: Small machines may use about 5 kW, while larger machines can need over 4000 kW.

Cycle Time: Producing one part can take from a few seconds to minutes, based on part complexity and size.

Cost Factors: Costs vary with machine size, material, and part complexity. Small machines might cost around $25,000, but larger ones can be over $1,000,000.

Historical Overview of Material Usage in Injection Molding

Beginnings:

Injection molding initially served mainly for plastics, beginning with celluloid in the late 19th century.

First Successes: Combs and buttons made from celluloid marked the first major success in plastic injection molding.

Material Expansion:

The method later embraced various plastics like polyethylene and polypropylene, valued for their durability and flexibility.

Venturing Beyond Plastics: Recent advancements now allow the use of metals and ceramics.

Material Evolution:

Innovations: New high-performance polymers and composites have emerged, offering increased strength and heat resistance.

Sustainability Efforts: There’s a rising trend in using recycled and bio-based materials, driven by environmental concerns.

For more details, explore the Injection Molding Wikipedia page.

Injection Molding with Non-Plastic Materials

Injection molding, a process known primarily for plastic manufacturing, has made significant strides in incorporating non-plastic materials, broadening its applications.

Metals and Injection Molding: The Process of Metal Injection Molding (MIM)

Process and Efficiency:

Method: Metal Injection Molding (MIM) blends fine metal powders with a polymer binder, which is then molded and sintered.

Efficiency: MIM is particularly effective for producing small, complex parts, offering a reduction in waste by up to 90% compared to traditional machining.

Cost and Power Consumption:

Cost-Effectiveness: MIM reduces production costs by approximately 20-30% for complex parts.

Energy Use: MIM uses about 50-60% less energy than traditional forging or machining processes.

Using Ceramic Materials in Injection Molding

Technical Aspects:

Precision: Ceramic injection molding achieves tolerances within 0.5% of the desired dimensions.

Strength and Durability: Ceramic parts exhibit high temperature and wear resistance.

Economic Factors:

Initial Costs: Setup costs for ceramic molding are higher, about 25-35% more than conventional methods.

Production Costs: However, per-part production costs can be lower by up to 20% for large-scale runs.

Glass and Other Unconventional Materials in Injection Molding

Innovation in Materials:

Process Adaptation: Glass injection molding requires temperatures up to 1,600°C, much higher than typical plastic molding.

Quality Control: Maintaining consistency in glass parts requires precise control, with less than 1% margin for error.

Cost Implications:

Equipment Expense: Specialized equipment for glass molding increases initial investment by approximately 40-50%.

Production Efficiency: Despite higher setup costs, per-unit production cost can be lower for bulk orders, saving up to 15-20% compared to traditional glass shaping methods.

For more detailed insights, you can visit the Wikipedia pages on Metal Injection Molding and Ceramic Injection Molding.

Comparative Analysis of Materials in Injection Molding

In injection molding, different materials offer unique properties and applications. A comparative analysis of plastics, metals, and ceramics provides insights into their suitability for various manufacturing needs.

Plastics vs. Metals: Properties and Applications

| Aspect | Plastics | Metals |

|---|---|---|

| Density (g/cm³) | 0.90-2.2 (e.g., PE, PVC) | 7.87 (Steel), 2.70 (Aluminum) |

| Melting Point (°C) | 130-260 (Common plastics) | 1,370 (Steel), 660 (Aluminum) |

| Tensile Strength (MPa) | 25-100 (Common plastics) | 400-550 (Steel), 110-310 (Aluminum) |

| Cost Efficiency | Generally lower cost; Economical for large-scale production | Higher cost but optimal for high-strength applications |

| Energy Consumption | Lower energy requirements for processing | Higher due to intense heating and cooling |

| Applications | Consumer goods, packaging | Aerospace, automotive components |

Plastics offer versatility and cost-effectiveness, ideal for a wide range of consumer products. Metals, with higher strength and melting points, are suited for applications demanding durability and high structural integrity.

Ceramics and Plastics: A Comparative Study

| Aspect | Ceramics | Plastics |

|---|---|---|

| Hardness | Extremely high; Resistant to wear and heat | Lower; varies across types |

| Flexibility | Brittle, low flexibility | High flexibility; varies with plastic type |

| Thermal Resistance | High; withstands extreme temperatures | Lower; susceptible to deformation |

| Manufacturing Cost | Higher due to complex processing | More cost-effective; simpler processing |

| Typical Use Cases | Aerospace, medical devices | Household items, electronic casings |

While ceramics provide unmatched hardness and thermal resistance, making them ideal for specialized applications, plastics are more adaptable and economically viable for a broader range of products.

For further exploration, the Wikipedia pages on Injection Molding, Plastics, Metals, and Ceramics offer extensive information.

Technological Innovations in Injection Molding

Recent advancements in injection molding technologies have significantly broadened the scope of materials and applications, ushering in a new era of manufacturing possibilities.

Advanced Materials in Injection Molding

High-Performance Polymers:

Properties: These polymers, like PEEK (Polyether Ether Ketone), offer exceptional heat resistance (up to 260°C) and strength, with tensile strengths of about 90-100 MPa.

Cost and Usage: While the cost is higher than standard plastics (about $90 per kilogram for PEEK compared to $2-3 for common plastics), their use in aerospace and medical industries justifies the expense due to their superior properties.

Biodegradable Plastics:

Sustainability: Materials like PLA (Polylactic Acid) are gaining popularity for being environmentally friendly, decomposing in under a year under the right conditions.

Efficiency: PLA has a similar molding process and energy requirements to conventional plastics, making it an easy switch for manufacturers.

Future Materials and Their Potential in Injection Molding

Graphene-Infused Plastics:

Enhanced Properties: Graphene, known for its strength and conductivity, can significantly improve the electrical and thermal properties of plastics.

Cost Implications: The current high cost of graphene (around $100 per gram) limits its widespread use, but with scaling production, costs are expected to decrease.

Smart Materials:

Innovation: Materials with properties that change in response to external stimuli (like temperature or light) are on the horizon. These could revolutionize product design, offering dynamic functionality.

Development Stage: While still in the research phase, these materials show great promise for future applications in various fields.

For more in-depth information, the Wikipedia pages on Injection Molding, PEEK, PLA, and Graphene provide valuable insights.