The size limit for injection molding can vary significantly, accommodating parts ranging from a few millimeters to several meters in length or width.

Understanding Injection Molding

Basics of Injection Molding Process

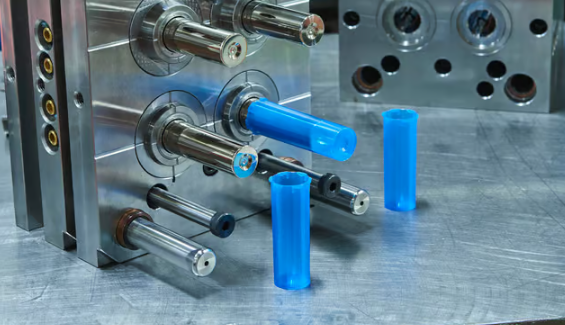

Injection molding, a manufacturing process, produces parts by injecting molten material into molds. This process unfolds through several critical stages:

Material Selection: Selecting the appropriate material is crucial. Manufacturers often use plastics like ABS and polycarbonate, along with eco-friendly alternatives.

Mold Design: The quality and production efficiency hinge on the mold’s design. Typically, manufacturers use steel or aluminum for molds, with design complexity influencing the cost.

Injection and Cooling: The process involves injecting molten material into the mold under high pressure, followed by a cooling phase. The cooling duration varies based on part thickness and material type.

Ejection and Finishing: After cooling, the part undergoes ejection, followed by any necessary post-processing, such as painting or assembly.

Materials Used in Injection Molding

The choice of materials in injection molding brings a range of advantages and challenges:

Thermoplastics, like Polyethylene and Nylon, are popular for their adaptability and recyclability. These materials, melting between 120-180°C, suit a diverse array of products.

Thermosetting Plastics differ as they cannot remelt. They provide excellent heat resistance but pose greater challenges in processing.

Elastomers, used for flexible parts, offer unique qualities such as stretchability, making them ideal for products like seals and gaskets.

Biodegradable Plastics are emerging as an environmentally friendly alternative, with properties similar to traditional plastics but with easier breakdown in the environment.

Size Limitations in Injection Molding

Factors Influencing Size Limits

Several factors determine the size limits in injection molding. These include:

Mold Size and Complexity: Larger molds require more material and are more complex to design and manufacture.

Machine Capacity: The clamping force and shot size of the molding machine dictate the maximum size of the part.

Material Characteristics: Different materials have varying shrinkage rates and flow characteristics, affecting the achievable size.

Wall Thickness: Thinner walls in larger parts can lead to issues like warping or incomplete filling.

Comparing Different Molding Machines

When comparing molding machines, it’s essential to consider various parameters that affect their suitability for large parts. Here’s a comparison table for reference:

| Machine Feature | Small Machines | Medium Machines | Large Machines |

|---|---|---|---|

| Clamping Force | 5-200 Tons | 200-500 Tons | 500-4000 Tons |

| Shot Size | Up to 2 oz | 2-10 oz | 10-100 oz |

| Power Consumption | Lower | Moderate | Higher |

| Cost | Lower | Moderate | Higher |

| Footprint | Smaller | Medium | Larger |

| Suitability for Large Parts | Low | Moderate | High |

Advantages of Larger Machines:

Can produce larger parts

Higher clamping force ensures better part quality

Limitations:

Higher cost and power consumption

Require more space

Understanding these dynamics is crucial, as detailed in resources like the Injection Molding Handbook.

Design Considerations for Injection Molding

Designing for Size Constraints

When designing for injection molding, size constraints are a significant consideration. Designers must ensure that the part fits within the machine’s capabilities while meeting the intended application’s requirements.

Maximizing Part Size: The largest achievable part size typically ranges from 200-600 mm in length, with a thickness of 0.5-5 mm. These dimensions are crucial to prevent defects like warping or sink marks.

Mold Design: A complex mold can increase costs significantly. For a medium complexity mold, costs can range from $3,000 to $6,000, while highly complex molds may exceed $20,000.

Balancing Size and Strength in Designs

Ensuring the balance between size and strength in injection molded parts is essential.

Material Selection: High-strength materials like reinforced plastics can add durability without significantly increasing size. The cost of these materials, however, can be 20-50% higher than standard plastics.

Wall Thickness: Maintaining uniform wall thickness between 1-3 mm is critical for structural integrity. Thicker walls provide strength but increase cooling time and material usage, thus impacting cost and cycle time.

Rib Design: Integrating ribs can enhance strength without increasing overall size. Ribs should be about 60-70% of the wall thickness to optimize strength and reduce material usage.

For more detailed insights into the materials and methods used in injection molding, refer to resources like the Injection Molding Materials Guide.

Technological Advances Affecting Size Limits

Innovations in Molding Equipment

Recent advancements in molding equipment have significantly expanded size limits in injection molding. These innovations focus on enhancing machine capacity and efficiency.

Increased Clamping Force: Modern machines offer clamping forces up to 5000 tons, enabling larger molds and parts.

Improved Precision Control: Advanced control systems regulate parameters like temperature and pressure with greater precision, ensuring consistent quality in larger parts.

Energy Efficiency: Newer machines consume less energy, with some models achieving up to 20-30% reduction in power consumption compared to older models.

Cost Implications: While these high-performance machines come at a higher initial cost, they offer long-term savings in energy efficiency and maintenance.

Material Developments and Size Capacity

Material science has also played a pivotal role in pushing the size boundaries in injection molding.

High-Performance Thermoplastics: New materials like PEEK and LCP (Liquid Crystal Polymer) offer superior strength and temperature resistance, allowing for larger part production without compromising quality.

Composite Materials: The integration of fibers like carbon or glass in plastics has led to materials that are both lightweight and strong, ideal for large-scale applications.

Bioplastics Development: Innovations in bioplastics are making them more viable for larger parts, with improved strength and heat resistance.

For an in-depth understanding of these advancements, resources such as the Injection Molding Technology Guide offer valuable information.