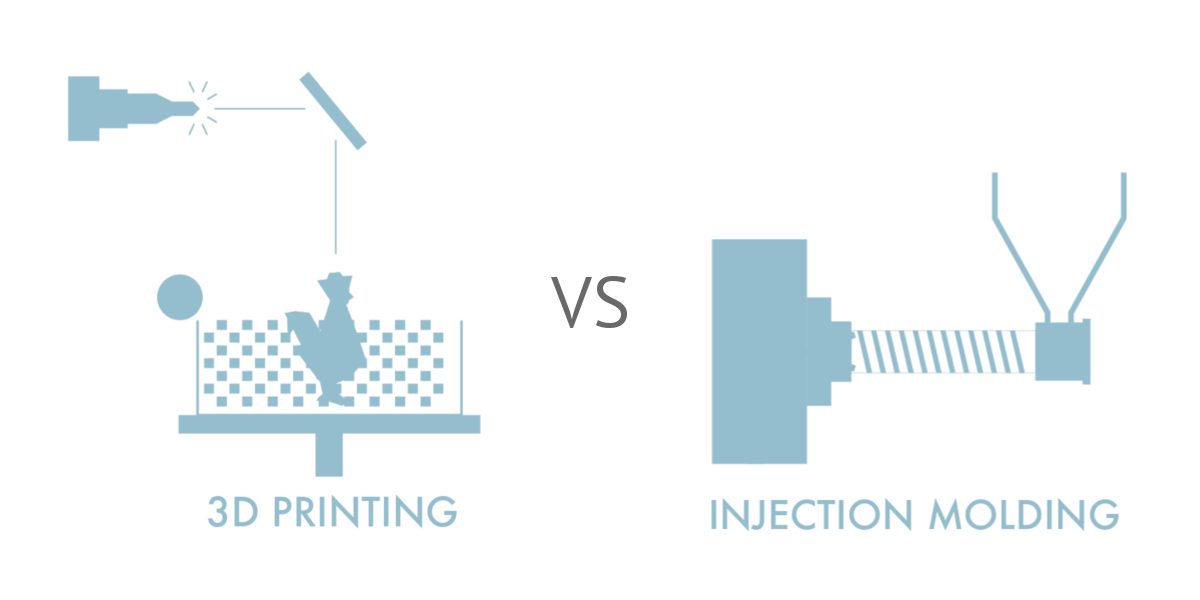

Injection molding uses molds to form materials, while 3D printing builds objects layer-by-layer from digital designs.

Basic Principles of Each Process

Injection molding and 3D printing are both pivotal techniques in the world of manufacturing, each with its unique set of principles and mechanics. Here, we will delve into the underlying processes that drive each method.

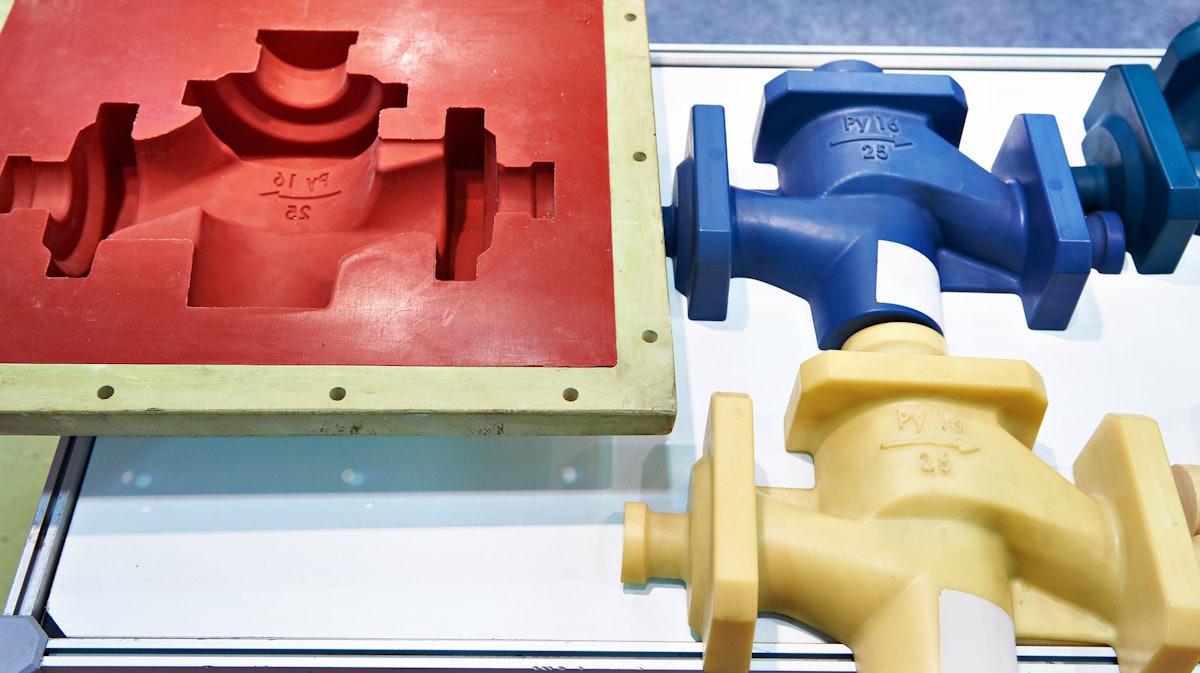

How Injection Molding Works

- Material Selection: Most often, thermoplastic polymers are used, which are melted to form the desired product. The selection depends on the product’s required strength, flexibility, and application.

- Mold Creation: This mold will give shape to the final product.

- Melting and Injecting: The chosen material, typically in pellet form, is heated until it becomes molten.

- Cooling and Solidifying: Once inside the mold, the material begins to cool and solidify, taking the shape of the mold.

- Ejection: After the product has solidified, it is ejected from the mold, and the process can be repeated.

- Post-processing: This may involve tasks like removing excess material or polishing to achieve the desired finish.

How 3D Printing Works

- Design Phase: The process begins with a digital 3D design, often created using CAD (Computer-Aided Design) software.

- Material Selection: A wide range of materials can be used for 3D printing, from thermoplastics to resins, and even metals. The choice largely depends on the printer type and the desired properties of the final object.

- Layer-by-layer Printing: 3D printing, also known as additive manufacturing, works by adding material layer by layer. The printer reads the digital file and deposits material accordingly.

- Solidifying: Depending on the type of 3D printer, the material might be solidified using UV light, heat, or chemical reactions.

- Post-processing: After printing, the object might need further refinement, such as sanding or painting, to achieve the desired finish.

Materials Used

The choice of materials in manufacturing is pivotal, determining not just the appearance but also the functionality, durability, and environmental impact of the final product. Here, we will explore the materials commonly used in both injection molding and 3D printing.

Common Materials in Injection Molding

- Polystyrene (PS): A versatile plastic used for everything from disposable cutlery to CD cases.

- Polyethylene (PE): Found in various densities, it’s the most common plastic. You’ll find it in products like plastic bags, bottles, toys, and more.

- Polypropylene (PP): Known for its flexibility, it’s used in automotive parts, containers, and living hinges.

- Polyethylene Terephthalate (PET): Commonly found in food packaging and plastic bottles.

- Polycarbonate (PC): Known for its high impact strength, it’s used in eyewear lenses and optical discs.

Suitable Materials for 3D Printing

- PLA (Polylactic Acid): A biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. Often used for prototyping and in the creation of consumer goods.

- ABS (Acrylonitrile Butadiene Styrene): A common thermoplastic polymer, it’s known for its strength and flexibility, often used in automotive and consumer goods.

- TPU (Thermoplastic Polyurethane): Combining the properties of elastomers and plastics, it’s flexible and is used in items like footwear and medical devices.

- Resins: Used in SLA (Stereolithography) 3D printing, these are photosensitive and solidify when exposed to UV light.

- Metals: Many metals like titanium, stainless steel, and aluminum can be used in 3D printing, particularly in Direct Metal Laser Sintering (DMLS) processes.

- Nylon (Polyamide): A durable material offering high flexibility, often used for tools, functional prototypes, and wearables.

Cost Implications

Every manufacturing process comes with its own set of cost considerations. These expenses affect the decision-making process for businesses, impacting the final product’s pricing and accessibility to consumers.

Initial Setup and Equipment Cost for Injection Molding

- Mold Creation: Designing and manufacturing a mold is often the most expensive part. Depending on complexity, molds can cost thousands to hundreds of thousands of dollars.

- Machine Cost: Industrial injection molding machines, depending on size and capability, can range from tens of thousands to over a million dollars.

- Facility Requirements: Injection molding machines require significant space and infrastructure, leading to higher facility costs.

Equipment and Operational Costs for 3D Printing

- Printer Cost: Depending on the type (FDM, SLA, SLS, DMLS), 3D printers can range from a few hundred dollars for basic models to several hundred thousand dollars for industrial machines.

- Material Cost: While some materials like PLA might be relatively inexpensive, others, especially metals or specialized resins, can be costlier.

- Maintenance: Regular cleaning and calibration are essential to ensure consistent print quality.

Scale and Production Capacity

For businesses, it’s essential to align production capabilities with market demands. The choice between injection molding and 3D printing will often depend on the scale and speed required.

Production Speed of Injection Molding

- Rapid Production: Once the mold is ready, injection molding can produce parts at a very high rate, making it suitable for large-scale production.

- Cycle Time: Depending on the part’s complexity and size, a cycle can range from a few seconds to a few minutes.

- Consistency: The process ensures high repeatability, producing consistent parts throughout the production run.

Production Limitations of 3D Printing

- Layer-by-layer Process: 3D printing’s additive nature means that it can be slower, especially for solid, large parts.

- Size Limitations: The build volume of the printer determines the maximum size of the part that can be produced.

- Material Constraints: Some advanced materials might require specialized printers or post-processing techniques, potentially slowing down the overall production timeline.

Quality and Accuracy

The quality and precision of products in manufacturing aren’t just about aesthetics; they play crucial roles in functionality, safety, and consumer trust.

Surface Finish in Injection Molding vs. 3D Printing

- Injection Molding: This process often results in smooth finishes directly out of the mold, especially when using polished molds. However, cosmetic imperfections like weld lines or sink marks can sometimes appear.

- 3D Printing: Due to its layer-by-layer approach, 3D printed objects can show layer lines, especially in FDM printing. Post-processing (like sanding or chemical smoothing) can be necessary to achieve a polished finish.

Tolerances and Precision in Both Processes

- Injection Molding: Capable of producing parts with tight tolerances. The precision can be as accurate as ± 0.002 inches, making it ideal for intricate components.

- 3D Printing: The accuracy depends on printer type, calibration, and material. SLA printers, for instance, can achieve layer heights of just 25 micrometers, ensuring a high level of detail.

Design Flexibility

The freedom to design plays a significant role in product innovation. But each manufacturing method comes with its own set of design considerations.

Design Constraints in Injection Molding

- Mold Constraints: Complex geometries might need multipart molds or side-actions, increasing mold complexity and cost.

- Draft Angles: Parts typically need draft angles to ensure they can be ejected from the mold without damage.

- Uniform Wall Thickness: Consistent thickness is crucial to prevent defects like warping or sink marks.

Design Freedom in 3D Printing

- Complex Geometries: One of 3D printing’s strengths is its ability to produce complex and intricate designs, which would be challenging or impossible with traditional manufacturing methods.

- No Tooling: Since there’s no need for molds, design changes can be made quickly and without significant cost implications, fostering rapid prototyping.

- Integrated Parts: With 3D printing, designers can produce assemblies in one print, eliminating the need for joining separate parts.

Applications and Use Cases

Here’s a deep dive into the sectors leveraging these processes and the unique use cases for each.

Industries Relying on Injection Molding

- Automotive: From dashboard components to door handles, injection molding is a mainstay in automotive production due to its ability to produce durable and consistent parts in bulk.

- Packaging: Everything from bottle caps to containers benefits from the rapid production rates of injection molding.

- Toys: Many toys, from action figures to LEGO bricks, are manufactured using this method, capitalizing on its ability to reproduce intricate designs on a large scale.

Emerging and Traditional Uses for 3D Printing

- Medical: Custom implants, dental crowns, and even bioprinting of tissues have become feasible due to the precision and customization possibilities of 3D printing.

- Fashion: From intricate jewelry designs to avant-garde clothing pieces, 3D printing allows designers to bring unique concepts to life.

- Education: 3D printers are becoming common in schools and universities, facilitating hands-on learning and fostering creativity among students. They allow for the tangible realization of concepts, from historical artifacts to molecular models.