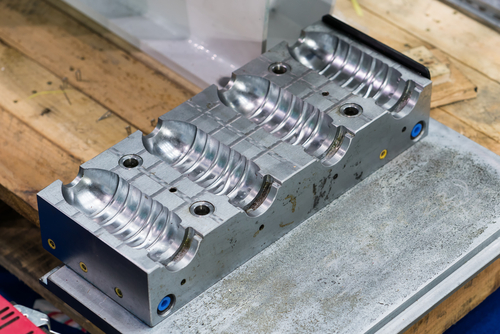

Injection molds are made of steel due to its exceptional durability, precise detailing capabilities, and ability to produce consistent, high-quality outputs.

Physical Properties of Steel

Steel, primarily an alloy of iron and carbon, offers a combination of properties that make it an ideal material for various applications, including injection molds. This section delves deep into the critical physical properties of steel that play a pivotal role in its selection for injection mold manufacturing.

Hardness and Wear Resistance

Steel possesses high hardness, especially when heat-treated. This intrinsic hardness allows steel molds to withstand the abrasive nature of many plastics that flow across the mold during the injection molding process. The enhanced wear resistance means that the molds can be used for extended periods without showing signs of wear or degradation. Tools made from harder steel grades can produce more parts over their lifecycle, reducing the need for frequent replacements.

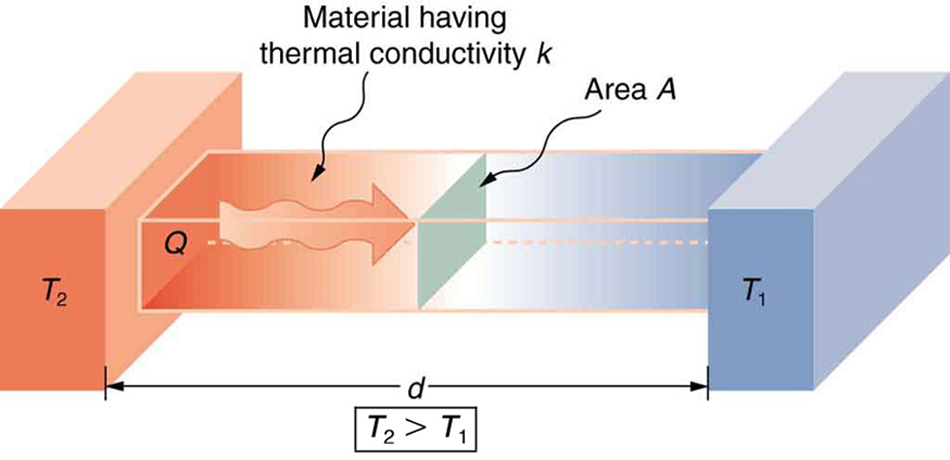

Thermal Conductivity

One of the unsung properties of steel that contributes to its suitability for injection molds is its thermal conductivity. Good thermal conductivity ensures that the mold heats and cools uniformly. This uniform heating and cooling are vital for the consistent quality of molded parts. Uneven temperatures can lead to defects in the molded part, such as warping or sink marks. When the mold heats uniformly, it can reduce cycle times and improve production efficiency.

Machinability

Machinability refers to the ease with which steel can be cut, shaped, and finished using machine tools. Steel’s good machinability ensures that molds can be intricately designed with fine details and surface finishes. This property becomes critical when creating molds for parts with complex geometries or when high precision is required. Superior machinability translates to faster production times and reduced tool wear, further making steel a preferred choice.

Economic Advantages of Steel Molds

The decision to use steel in injection molds isn’t solely based on its physical properties. Economically speaking, steel molds provide several advantages that contribute to their widespread adoption in industries. Some of these economic advantages include:

- Reduced production downtimes: Since steel molds are durable, they demand less frequent repairs or replacements.

- Consistent product quality: The longevity and resilience of steel ensure consistent product output.

- Higher return on investment: Given their lifespan, steel molds typically offer a better ROI compared to molds made from other materials.

- Flexibility in design changes: Due to steel’s machinability, modifications to mold design can be made with relative ease.

Longevity and Durability

Steel’s inherent strength and resistance to wear ensure that molds made from this material have a long service life. As a result, industries can produce a vast number of parts before there’s a need to replace or refurbish the mold. This longevity means that over the mold’s lifecycle, the cost per unit produced can be significantly lower than molds made of less durable materials.

Cost Efficiency over Time

While the initial cost of steel molds might be higher than those of alternative materials, their long service life ensures cost efficiency over time. Reduced wear and tear mean fewer interruptions in the production process and less expenditure on mold maintenance or replacement. Additionally, the consistent quality of parts produced reduces wastage, leading to more efficient production runs.

Availability and Supply Chain Benefits

Steel is one of the most widely produced and used materials globally, ensuring its ready availability. This widespread availability simplifies the supply chain, leading to faster delivery times and often reduced costs. Moreover, being a global commodity, steel prices are relatively stable, allowing manufacturers to predict their costs more accurately.

Quality of the End Product

Using steel molds in injection molding processes substantially influences the end product’s quality. The precision, durability, and consistency that steel molds bring to the table ensure that the final products meet the desired specifications and aesthetic standards. Key aspects influenced by steel molds include:

- Uniformity across batches: Consistent mold performance ensures that every batch of products retains the same quality.

- Enhanced visual appeal: Products molded using steel molds often have superior visual characteristics.

- Fewer recalls and returns: High-quality products translate to fewer defects, leading to reduced recalls or returns.

- Improved reputation: For manufacturers, consistently high-quality outputs bolster their market reputation, enabling better business opportunities.

Surface Finish and Detail

Steel’s smoothness and ability to retain intricate details during the molding process result in products with excellent surface finish and detail. Products come out of the mold with minimal post-production finishing needs, saving both time and resources. This is especially important in industries where aesthetics play a vital role, such as automotive or consumer electronics.

Dimensional Accuracy

Steel molds ensure that the molded products adhere to the exact dimensions specified in the design. This dimensional accuracy is critical in industries like aerospace, automotive, and medical devices, where even minute discrepancies can lead to significant problems. With steel molds, manufacturers can ensure that every product, from the first to the last in a production run, meets the desired specifications.

Reduced Defects

The resilience and consistency of steel molds contribute to a reduction in defects in the final products. Unlike molds made from softer materials, steel molds do not wear out quickly, ensuring that the product quality remains consistent throughout the mold’s lifecycle. This consistency minimizes the chances of defects like warping, sink marks, or incomplete fills, which can occur due to irregularities in the mold.

Comparative Analysis

The choice of material for injection molds significantly influences the mold’s performance, lifespan, and the quality of the end product. While steel remains a popular choice, other materials like aluminum, beryllium-copper, and composite materials have their specific advantages and use-cases. Let’s conduct a comparative analysis of these materials against steel.

Steel vs. Aluminum Molds

| Feature | Steel | Aluminum |

|---|---|---|

| Hardness | ✔ | ❌ |

| Thermal Conductivity | ❌ | ✔ |

| Lifespan | ✔ | ❌ |

| Machinability | ✔ | ✔ |

| Cost | ❌ (Higher Initial Cost) | ✔ (Lower Initial Cost) |

| Surface Finish | ✔ | ✔ |

While steel boasts superior hardness and a longer lifespan, aluminum excels in thermal conductivity and may offer cost benefits in short-run production. The Wikipedia page on aluminum can provide additional insights into its properties.

Steel vs. Beryllium-Copper Molds

| Feature | Steel | Beryllium-Copper |

|---|---|---|

| Hardness | ✔ | ❌ |

| Thermal Conductivity | ❌ | ✔ |

| Lifespan | ✔ | ❌ |

| Machinability | ✔ | ❌ |

| Cost | ❌ (Higher Initial Cost) | ❌ (Often Higher than Steel) |

| Corrosion Resistance | ❌ | ✔ |

Beryllium-Copper molds are known for their excellent thermal conductivity and corrosion resistance. However, they tend to be more expensive and might not be as hard or long-lasting as steel. More about Beryllium-Copper and its applications can be found on Wikipedia.

Steel vs. Composite Materials

| Feature | Steel | Composite Materials |

|---|---|---|

| Hardness | ✔ | ❌ |

| Thermal Conductivity | ✔ (Varies with steel type) | ❌ |

| Lifespan | ✔ | ❌ |

| Machinability | ✔ | ❌ |

| Cost | ❌ (Higher Initial Cost) | ✔ (Can be cost-effective depending on the composite) |

| Weight | ❌ (Heavier) | ✔ (Often Lighter) |

Environmental Considerations

In today’s world, the environmental impact of manufacturing and production processes has gained immense importance. Beyond the technical and economic factors, considering the ecological footprint of the materials and methods used is crucial for sustainable operations. When it comes to injection molding, several environmental considerations come into play, especially when evaluating the pros and cons of steel molds and their alternatives.

Recyclability of Steel Molds

Steel is one of the most recyclable materials on the planet. Almost all steel products, including molds, can be recycled without losing their inherent properties. Recycling steel molds reduces the need for virgin materials, leading to:

- A decrease in mining activities, thus preserving natural habitats.

- A reduction in energy consumption, as producing steel from recycled materials consumes less energy than producing it from raw iron ore.

- A decrease in landfill waste, given that old steel molds are repurposed rather than discarded.

Energy Consumption in Manufacturing

Manufacturing steel molds can be energy-intensive, primarily due to the processes involved in mining, refining, and shaping the steel. However, with advancements in steel production methods and increasing reliance on recycled steel, this energy consumption has been trending downwards.

Comparatively, producing alternative materials for molds may vary in energy consumption. For instance, the production of aluminum is notoriously energy-intensive, while certain composite materials might require less energy. An informed decision would weigh the mold’s lifespan, energy in production, and the overall ecological impact.

Environmental Impact of Alternative Materials

Alternative materials for molds, such as aluminum, beryllium-copper, and composites, have their own set of environmental considerations:

- Aluminum: While recyclable, its primary production is energy-intensive, and bauxite mining can have significant environmental impacts.

- Beryllium-Copper: The mining of beryllium can lead to habitat disruption. Additionally, worker safety is a concern due to beryllium’s potential health risks.

- Composite Materials: The environmental impact varies depending on the composite. Some composites may not be recyclable, leading to landfill waste. Others might involve the use of chemicals with potential environmental repercussions.