The shrinkage problem in injection molding refers to the material volume reduction as it cools and solidifies in the mold.

Understanding Shrinkage in Injection Molding

Injection molding is a widely used manufacturing process for producing plastic parts. In this process, understanding shrinkage — the reduction in size of a plastic part as it cools and solidifies — is crucial for achieving accurate dimensions and maintaining the high quality of the final product.

Definition of Shrinkage

Shrinkage is the contraction of a plastic part as it cools down from the processing temperature to room temperature. This phenomenon is significant in injection molding as it impacts the dimensional accuracy and integrity of the molded parts.

Types of Shrinkage

Post-mold Shrinkage

- Occurs after the part is ejected from the mold.

- Influenced by how the part cools outside the mold.

- Environmental conditions and the time taken for the part to reach ambient temperature can affect post-mold shrinkage.

In-mold Shrinkage

- Happens during the cooling phase in the mold.

- Adequate control of mold temperature and cooling rate is essential.

- Inconsistent cooling can cause dimensional inaccuracies and defects like warping or internal stresses in the product.

To address these shrinkage types, understanding specific shrinkage rates of materials is essential. For example, a material like high-density polyethylene (HDPE) may have a specified shrinkage rate which must be considered in mold design to ensure the final product’s dimensions are accurate.

Selecting the appropriate material with a suitable shrinkage rate is crucial for maintaining cost-effectiveness and quality. Incorrect material selection can lead to dimensional inaccuracies, increasing scrap rates and production costs.

Effective mold design significantly influences shrinkage control. A mold that does not facilitate uniform cooling can result in differential shrinkage, leading to defects in the final product. Using simulation software for predicting shrinkage can assist in designing molds that mitigate these issues.

Processing conditions such as melt temperature, injection speed, and pressure have a direct impact on shrinkage. For instance, higher temperatures generally increase the shrinkage rate due to greater expansion of the material before solidification. Adjusting these parameters is essential to minimize shrinkage while maintaining the desired production speed and quality level.

Shrinkage management is key to ensuring dimensional accuracy, enhancing production efficiency, and reducing material costs. Effective shrinkage control can lead to fewer iterations in design and prototyping, lower development times, and cost savings, whereas poor shrinkage management can result in increased development times and higher costs. Advanced materials, precision in mold design, and process optimization are crucial to addressing the challenges posed by shrinkage in injection molding.

Factors Contributing to Shrinkage

Shrinkage in injection molding results from various factors, including material properties, mold design, and processing conditions. Understanding these elements is vital for controlling the shrinkage and ensuring the production of high-quality parts.

Material Properties

Different materials behave differently under the injection molding process, significantly affecting shrinkage. For example, amorphous polymers like Polystyrene tend to have lower shrinkage compared to semi-crystalline materials like Polyethylene. The molecular structure and composition of the plastic, its thermal properties, and its flow behavior play a crucial role in determining how much the material will shrink. Materials with higher shrinkage rates may require more attention to detail in mold design and process control to compensate for these changes.

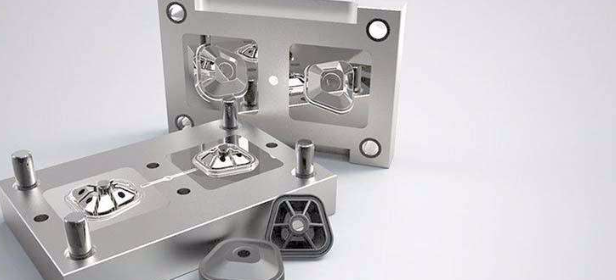

Mold Design

The design of the mold influences shrinkage in several ways. Key aspects include:

- Mold material: Different mold materials conduct heat differently, affecting how quickly the part cools and, thus, how much it shrinks.

- Mold temperature: A higher mold temperature usually results in less shrinkage as the material is able to flow and pack into the mold more effectively before cooling.

- Design features: Elements such as mold wall thickness, gate location, and ejection mechanism also impact shrinkage. For instance, thicker walls may lead to slower cooling and thus, differential shrinkage within the part.

Processing Conditions

Processing conditions in the injection molding machine significantly affect the amount of shrinkage.

Temperature

- The melt temperature is a critical parameter. Higher melt temperatures can lead to higher shrinkage due to the greater thermal expansion of the polymer during the melting phase. However, if the temperature is too low, it might lead to incomplete filling of the mold or increased internal stresses, both of which can adversely affect the dimensional stability and quality of the part.

Pressure

- Injection pressure and holding pressure have a direct impact on how the material packs and holds within the mold. Higher pressures generally allow for better packing, reducing shrinkage by filling in more material to compensate for the volume reduction as the part cools. However, excessive pressure can cause other defects like flash, where the material escapes the mold cavity.

Cooling Time

- Cooling time is another critical factor. Longer cooling times allow for more uniform shrinkage throughout the part, potentially reducing warpage and internal stresses. However, increased cooling times can lead to longer cycle times, affecting overall production efficiency and costs.

Measuring and Predicting Shrinkage

Accurately measuring and predicting shrinkage in injection molding is essential for producing parts that meet precise dimensional specifications. This process involves both empirical measurement techniques and advanced predictive modeling.

Shrinkage Measurement Techniques

Shrinkage measurement typically involves comparing the dimensions of the molded part with those of the mold or the original CAD model. Common techniques include:

- Direct Measurement: Using tools like calipers or micrometers, technicians measure the dimensions of the cooled part and compare them to the mold dimensions. This method is straightforward but can be time-consuming and subject to human error.

- CMM (Coordinate Measuring Machine): A CMM provides a highly accurate way to measure the dimensions of a part. By touching various points on the part’s surface with a probe, the CMM can precisely map its geometry. This method not only measures linear dimensions but can also assess complex geometries and forms.

- Laser Scanning: Laser scanners create a digital 3D representation of the part by scanning its surface. This technique is fast and can process complex shapes, making it ideal for detailed analysis. However, the initial cost of laser scanning equipment can be significant.

Predictive Modelling of Shrinkage

Predictive modeling involves using mathematical models and simulations to predict shrinkage before manufacturing begins. This approach can save both time and costs associated with trial-and-error methods.

- Finite Element Analysis (FEA): FEA simulates the molding process, including the flow of molten plastic into the mold, cooling, and solidification. By analyzing these elements, FEA can predict how and where shrinkage will occur, allowing designers to adjust the mold or processing parameters accordingly.

- Empirical Modeling: This method uses data from previous molding operations to build a model that predicts shrinkage based on specific materials and process conditions. Empirical models can be simpler than FEA but might not be as precise for new or significantly different materials or designs.

Role of Simulation Software

Simulation software plays a crucial role in predicting shrinkage in the injection molding process. Tools like Moldflow, SolidWorks Plastics, and ANSYS Polyflow offer sophisticated capabilities:

- Process Optimization: These simulations help optimize processing conditions such as temperature, pressure, and cooling time, directly impacting shrinkage.

- Mold and Part Design: Software can simulate the effects of different mold designs and material choices on shrinkage, helping to make decisions that balance quality, efficiency, and cost.

- Visualization of Shrinkage: Simulation tools provide visual feedback on where and how much shrinkage is likely to occur, allowing for a more intuitive understanding of shrinkage issues.

- Reduced Prototyping Needs: By accurately predicting shrinkage, these tools reduce the need for physical prototyping, which can be both costly and time-consuming.

Impact of Shrinkage

Shrinkage in injection molding can significantly impact the quality and functionality of the final product. Understanding how shrinkage affects part dimensions, mechanical properties, and aesthetics is crucial for manufacturers to ensure that their products meet all requirements and specifications.

Effect on Part Dimensions and Tolerances

Shrinkage directly influences the dimensions of a plastic part. Even a small amount of shrinkage can be critical, especially for components designed to fit precisely with other parts. Here are some detailed considerations:

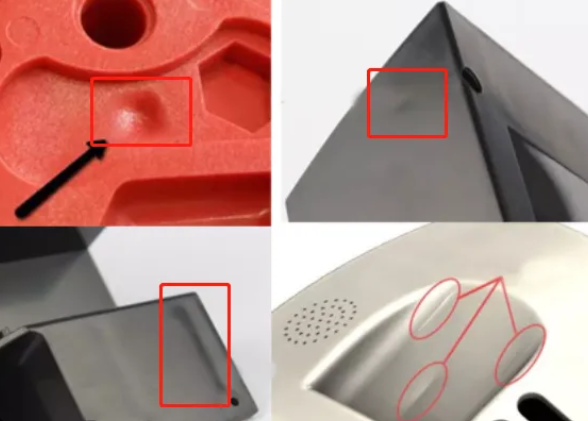

- Dimensional Inaccuracy: If shrinkage is not uniformly accounted for in the design and manufacturing process, it can lead to parts that are too small or too large, failing to meet the specified dimensions and tolerances.

- Fit and Function: For mechanical assemblies or parts intended to interface with other components, shrinkage can affect the fit, leading to assembly issues, loose or overly tight fits, and functional failures.

- Rejection Rates: Parts that deviate beyond the specified tolerances may need reworking or may be rejected outright, increasing costs and affecting overall production efficiency.

Impact on Mechanical Properties

Shrinkage can also affect the physical properties of a molded part, which can be particularly crucial for structural or load-bearing components.

- Stress and Warping: Uneven shrinkage can lead to internal stresses and warping, which can weaken the part or cause it to deform over time, affecting its mechanical performance and longevity.

- Impact on Strength: Variations in shrinkage can lead to inconsistencies in wall thickness, affecting the part’s strength and resistance to impact or stress.

- Material Behavior: Different materials may respond to shrinkage differently, potentially altering the expected material properties like tensile strength, flexibility, or hardness.

Aesthetic Implications

The appearance of a final product is essential, especially for consumer goods where visual appeal can significantly influence purchasing decisions.

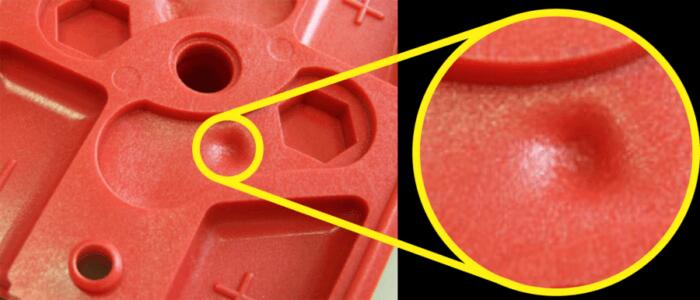

- Surface Finish: Shrinkage can lead to surface defects like sink marks or voids, which can mar the appearance of the part.

- Color and Texture Consistency: Uneven cooling and shrinkage can affect the distribution of colors and textures on the part surface, leading to aesthetic inconsistencies.

- Overall Quality Perception: Parts with visible defects or inconsistencies often are perceived as lower quality, potentially affecting brand reputation and consumer trust.

Managing and Controlling Shrinkage

Effective management and control of shrinkage are vital for maintaining the quality, functionality, and aesthetics of injection molded parts. This involves several strategies, including material selection, mold design, process optimization, and the use of additives.

Material Selection and Preparation

Choosing the right material and preparing it properly can significantly influence the shrinkage rate.

- Material Type: Different polymers exhibit different shrinkage rates. For example, amorphous materials like ABS and polycarbonate generally have lower shrinkage rates compared to semi-crystalline materials like polyethylene and polypropylene. Material selection thus plays a critical role in controlling shrinkage.

- Drying and Preprocessing: Moisture in polymer granules can lead to inconsistent melting and, subsequently, uneven shrinkage. Proper drying and preconditioning of materials are crucial to ensure consistent quality.

- Thermal Properties: Understanding the thermal characteristics of materials, such as their glass transition and melting temperatures, helps in setting the right processing parameters, thus controlling shrinkage.

Mold Design Strategies

The design of the mold significantly impacts how a material shrinks and cools.

- Mold Material and Design: Molds made from materials with high thermal conductivity (like aluminum) cool down faster, reducing cycle time but potentially increasing shrinkage. Adjustments in mold design, such as adding cooling lines, can help manage this.

- Wall Thickness: Uniform wall thickness promotes even cooling and shrinkage. Gradual transitions in thickness can prevent stress accumulation and minimize warpage.

- Gate Location and Size: The position and size of gates influence how the molten plastic fills the mold, which affects how it cools and shrinks. Strategic gate placement can ensure more uniform shrinkage.

Process Optimization Techniques

Optimizing the injection molding process parameters can help control shrinkage.

- Temperature Control: Precise control of mold and melt temperatures can influence how a part cools and shrinks. Higher mold temperatures generally reduce shrinkage but increase the cooling time.

- Injection Speed and Pressure: Adjusting the injection speed and pressure can help achieve a more uniform fill and packing phase, which in turn helps control shrinkage.

- Cooling Time: Longer cooling times allow for more uniform shrinkage and reduced internal stresses, but at the cost of longer cycle times. Finding an optimal balance is key to efficient production.

Use of Additives and Fillers

Additives and fillers can alter the shrinkage characteristics of the polymer.

- Fillers: Incorporating fillers like glass fibers or mineral fillers can reduce shrinkage, improve strength, and enhance thermal properties. However, they can also affect the color and transparency of the material.

- Additives: Certain additives can be used to control shrinkage, improve flow characteristics, or enhance other properties like UV resistance.

Case Studies

Analyzing case studies in injection molding, particularly those focusing on shrinkage control, can provide valuable insights and practical lessons. These studies help in understanding both the successes in managing shrinkage and the lessons learned from failures.

Analysis of Successful Shrinkage Control

Success stories in shrinkage control often involve a combination of meticulous material selection, precise mold design, and optimized processing parameters.

- Automotive Component Case Study: In one instance, an automotive manufacturer faced challenges with inconsistent shrinkage leading to part failures. The solution involved switching to a high-performance polymer with lower shrinkage characteristics and adjusting the mold design to have uniform wall thickness. This change not only resolved the shrinkage issue but also improved the overall durability and performance of the parts.

- Consumer Electronics Case Study: For a consumer electronics product, engineers successfully minimized shrinkage and warpage by optimizing the cooling system within the mold, ensuring faster and more uniform cooling. This step was crucial for maintaining the tight dimensional tolerances and high-quality surface finish required for these components.

Lessons from Shrinkage-related Failures

Analyzing failures related to shrinkage can be just as instructive, highlighting the importance of attention to detail in all stages of the injection molding process.

- Medical Device Failure Analysis: A medical device company experienced high rejection rates due to shrinkage-induced warping in a critical component. The analysis revealed that the cause was uneven wall thickness and inadequate cooling time. This experience underscored the need for careful mold design and process parameter settings, especially in high-precision applications where tolerances are extremely tight.

- Toy Manufacturing Failure Case: A toy manufacturer faced aesthetic issues and functional failures due to shrinkage. It turned out that the rapid cooling rate and the use of an incorrect type of plastic were to blame. This case highlighted the importance of choosing the right material and carefully controlling the molding temperature and cooling rates to achieve the desired quality and functionality.