Raw materials in fabrication include metals, plastics, ceramics, natural materials, and advanced composites.

Metals and Alloys

Metals and alloys have always played a fundamental role in fabrication processes. They are versatile, durable, and can be manipulated into a myriad of forms. Their inherent properties such as malleability, tensile strength, and electrical conductivity make them indispensable in various industries. From the construction sector to electronics, metals and alloys remain the backbone of manufacturing.

Steel and its Types

Steel, an alloy primarily of iron and carbon, has multiple types based on its composition and processing:

- Carbon Steel: Contains up to 2.1% carbon. It’s the most widely used form and is categorized further into low, medium, and high carbon steels.

- Alloy Steel: Features additional elements like nickel, chromium, and molybdenum to impart specific properties.

- Stainless Steel: Known for its corrosion resistance, it contains a minimum of 10.5% chromium. More about Stainless Steel on Wikipedia

- Tool Steel: Primarily used for manufacturing tools due to its hardness, abrasion resistance, and ability to withstand high pressures.

Aluminum and its Alloys

Lightweight and versatile, aluminum and its alloys are fundamental in sectors like aerospace, automotive, and packaging:

- Pure Aluminum: Soft and ductile, it’s mostly used for electrical transmission lines and packaging.

- Heat-treatable Alloys: Such as 6061 and 2024, these are primarily used in aircraft structures.

- Non-heat-treatable Alloys: Examples include 3003 and 5052, which are applied in cooking utensils and other applications.

Copper and its Alloys

Copper is known for its excellent electrical conductivity. Its alloys usually enhance its properties for specific applications:

- Bronze: An alloy of copper and tin. It’s widely used for statues, medals, and coins.

- Brass: Combines copper and zinc, finding its applications in musical instruments and decorative items. More about Brass on Wikipedia

Titanium and its Alloys

Recognized for its impressive strength-to-weight ratio and corrosion resistance, titanium is invaluable in aerospace and medical fields:

- Alpha Titanium Alloys: Non-heat treatable and possess a lower strength but superior formability.

- Beta Titanium Alloys: Heat-treatable and have a higher strength compared to alpha alloys.

Precious Metals in Fabrication

Not just valued for their rarity and beauty, precious metals find extensive functional applications:

- Gold: Apart from jewelry, it’s utilized in electronics due to its excellent conductivity and resistance to tarnish.

- Silver: Used in solar panels, jewelry, and as an antimicrobial agent.

- Platinum: Finds application in catalytic converters and lab equipment.

Plastics and Polymers

Plastics and polymers dominate a significant portion of modern fabrication, given their versatility, ease of production, and diverse range of properties. From the packaging industry to medical equipment, they’re essential in nearly every sector. Being synthetic or semi-synthetic organic compounds, they offer customization that can meet specific requirements.

Thermoplastics vs. Thermosetting Plastics

When it comes to plastics, understanding their behavior under heat is crucial. The primary distinction comes down to how they react:

- Thermoplastics: These are materials that become moldable upon heating and solidify upon cooling. Common examples include:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl Chloride (PVC)

- Polycarbonate (PC)

- Examples include:

- Epoxy Resin

- Phenolic Resins

- Melamine

Commonly Used Plastics in Fabrication

Many plastics have carved their niche in fabrication because of specific properties:

- Polyethylene (PE): Recognized for its flexibility and chemical resistance, it’s commonly used in packaging films and bottles.

- Polyvinyl Chloride (PVC): Widely known for its use in plumbing, it’s also essential in electrical cable insulation.

- Polystyrene (PS): Given its ease of molding and rigidity, it’s favored for packaging and insulation.

- Polyethylene Terephthalate (PET): Commonly used for making bottles and other packaging materials.

Advantages of Plastic Fabrication

Plastic fabrication brings several benefits to the table:

- Versatility: A broad range of properties can be achieved by tweaking polymer structures or adding fillers and additives.

- Cost-Efficiency: Generally, plastic production can be more economical compared to metals, especially for large-scale manufacturing.

- Lightweight: Especially crucial in industries like automotive and aerospace where weight impacts efficiency.

- Corrosion Resistance: Unlike many metals, plastics generally don’t corrode, making them suitable for long-term applications in harsh environments.

Ceramics and Glasses

Historically, they’ve been paramount for their durability, aesthetic appeal, and vast array of applications. In today’s world, they remain essential not just for their traditional uses but also in advanced technologies and industries.

Properties and Uses of Ceramics

Ceramics are non-metallic, inorganic solids that exhibit a variety of properties, making them suitable for numerous applications:

- Hardness: Many ceramics, like alumina, are hard and wear-resistant.

- Thermal Stability: They can withstand high temperatures, making them ideal for applications like jet engine components.

- Electrical Insulation: Many ceramics don’t conduct electricity, so they’re used in electrical insulation applications.

- Biocompatibility: Certain ceramics are compatible with living tissue, leading to their use in medical implants.

- Uses: From pottery to superconductors, ceramics find applications in a broad range of industries.

Different Types of Glass Used in Fabrication

Glass, a transparent or translucent material, primarily consists of silica combined with various additives:

- Soda-Lime Glass: The most common type, often used in windows and bottles.

- Borosilicate Glass: Resistant to thermal shock, it’s frequently used in lab equipment and cookware.

- Lead Glass: Known for its clarity and brilliance, it’s popular for decorative purposes and in electronics.

- Tempered Glass: Heated and then rapidly cooled, this type of glass is four times stronger than regular glass and is employed in car windows and some mobile devices.

Ceramic-Metal Composites in Fabrication

Merging the world of metals and ceramics gives birth to materials that harness the advantages of both:

- Enhanced Strength: The combination often results in composites that are stronger than either of the constituents on their own.

- Thermal Stability: The ceramic component offers resistance to high temperatures.

- Applications: From cutting tools that retain sharpness for longer to biomedical implants that utilize the biocompatibility of ceramics, the potential uses are vast.

Natural Materials

Natural materials, directly harvested from the environment, have been instrumental throughout human history. They play a foundational role in numerous applications, from construction to artistry. Their appeal often stems from their innate beauty, biodegradability, and rich historical significance.

Wood and its Types

Wood has been an invaluable resource for countless applications, from building structures to crafting furniture:

- Softwoods: Trees like pine, cedar, and spruce produce these. They are typically lighter in color and used for construction and crafting.

- Hardwoods: Derived from trees like oak, walnut, and maple. Renowned for their durability, they’re preferred for premium furniture and flooring.

- Exotic Woods: Such as mahogany, teak, and rosewood, are prized for their unique appearance and often utilized for specialty products.

Stone and Masonry in Fabrication

Stone, with its enduring and unyielding nature, has been fundamental in building and art:

- Granite: A hard stone often used for kitchen countertops due to its resilience against scratches.

- Marble: Prized for its elegance, utilized predominantly in statues, tiles, and premium architecture.

- Slate: Known for its fine grain, it’s a top choice for roofing tiles and chalkboards.

- Masonry: The art of building with brick, stone, or concrete units. A timeless technique ensuring structures of great strength and longevity.

Leather and Fabric Materials

From attire to upholstery, these materials have always been vital for human comfort and expression:

- Leather: Processed from animal skins, it’s versatile, durable, and widely used for shoes, belts, bags, and luxury seating.

- Cotton: Soft and breathable, it’s the backbone of the textile industry, creating everything from t-shirts to bed linens.

- Silk: Known for its shimmer and smoothness, silk is the epitome of luxury in fabrics. Its applications range from scarves to evening gowns.

Composite Materials

Composite materials are engineered by combining two or more distinct materials to harness the best properties of each. They revolutionize industries by offering enhanced strength, durability, and functionality, often without adding significant weight or complexity.

Definition and Importance of Composites

Composites consist of a matrix and a reinforcement. The matrix binds the materials together, while the reinforcement boosts its overall strength and stiffness. The combination leads to a material with unique properties, often unattainable by its individual components.

- Strength to Weight Ratio: Composites often offer significant strength without a corresponding increase in weight.

- Corrosion Resistance: Many composites resist environmental degradation better than traditional materials.

- Design Flexibility: Composites can be molded into complex shapes, allowing more design freedom.

- Importance: From aerospace to automotive sectors, composites enable the creation of lighter and stronger materials, paving the way for innovations and more efficient designs.

Carbon Fiber Reinforced Polymers (CFRP)

CFRP is a type of composite material that combines carbon fibers with a polymer matrix, leading to a material that’s lightweight yet remarkably strong.

- Aerospace: Due to its strength and lightness, CFRP is often used in aircraft structures.

- Sports Equipment: Bicycles, tennis rackets, and golf clubs benefit from CFRP’s strength-to-weight ratio.

- Automotive: High-performance cars incorporate CFRP to achieve superior strength without adding weight.

Fiberglass Composites

Consisting of fine glass fibers embedded in a resin matrix, fiberglass is both robust and lightweight.

- Construction: Fiberglass is frequently used as insulation and for roofing materials.

- Automotive: Car bodies, especially in high-performance vehicles, utilize fiberglass to minimize weight.

- Marine: Due to its resistance to water, fiberglass is a popular choice for boat hulls.

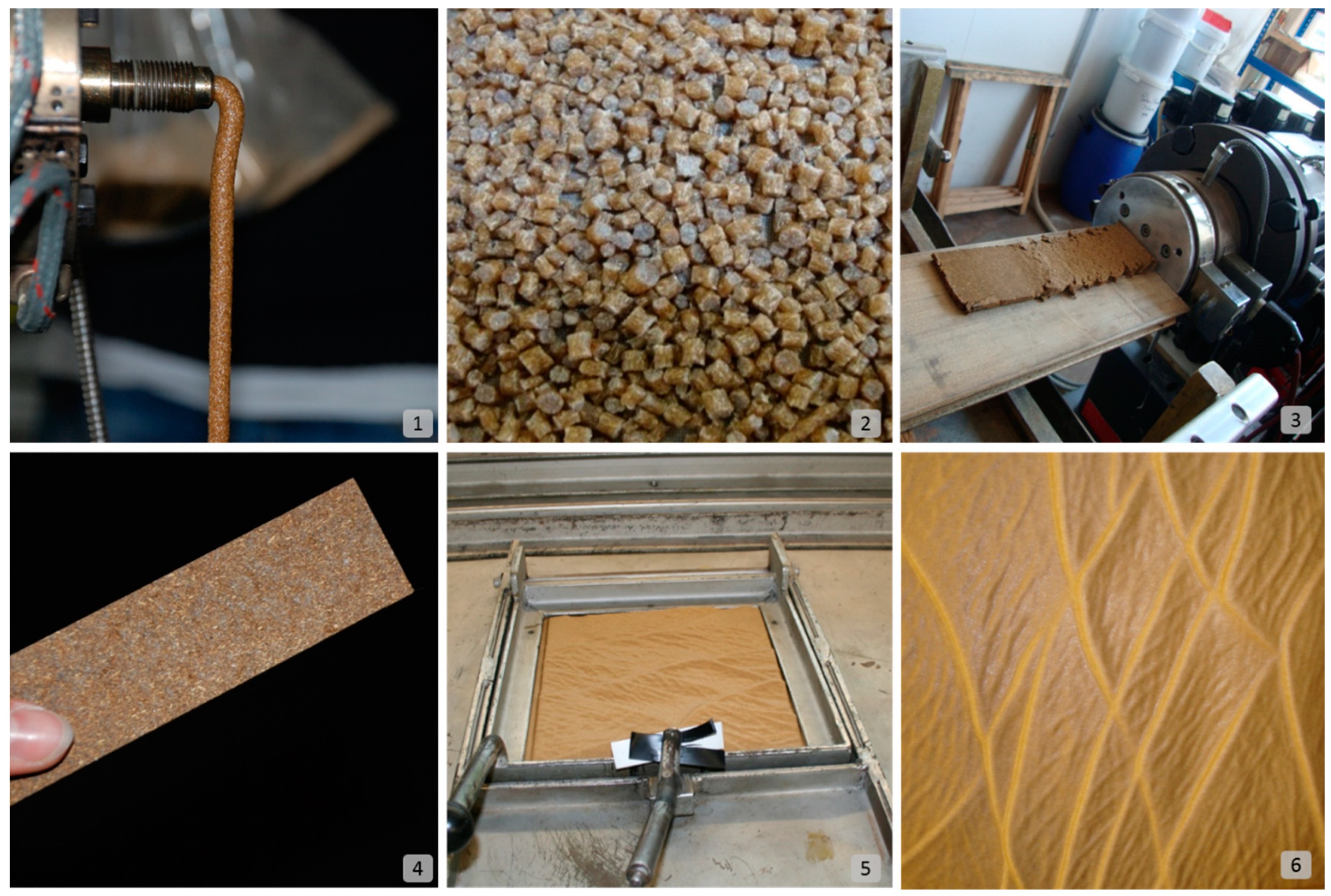

Natural Fiber Composites

These composites leverage fibers derived from natural sources, combining them with a matrix for enhanced properties.

- Jute, Hemp, and Flax: These plant-derived fibers find applications in automotive interiors and home products.

- Eco-friendliness: Often biodegradable and less energy-intensive to produce, making them a green choice.

- Applications: Used in automotive parts, furniture, and packaging due to their eco-friendly nature and adequate strength.

Emerging Materials in Fabrication

Innovations in material science have led to the emergence of new materials that not only challenge the status quo in terms of their capabilities but also drive industries towards more sustainable, efficient, and futuristic applications. Let’s delve into some of these groundbreaking materials.

Smart Materials

Smart materials respond dynamically to external stimuli such as temperature, pressure, or electric current, altering their properties in the process.

- Shape Memory Alloys: Metals that “remember” their original shape and can revert to it upon exposure to external stimuli. Common in some eyeglass frames and medical devices.

- Piezoelectric Materials: Generate electricity when subjected to mechanical stress, finding applications in sensors and energy harvesting.

- Thermochromic and Photochromic Materials: Change color in response to temperature or light changes, respectively.

Nanomaterials

Materials structured on the nanoscale (typically between 1 and 100 nanometers) that exhibit unique properties due to their size.

- Quantum Dots: Nanoscale semiconductor particles that have quantum mechanical properties, used in display technologies and solar cells.

- Nanocomposites: Combine nanoparticles with bulk materials to create composites with enhanced properties, finding applications in aerospace, automotive, and more.

Biodegradable and Sustainable Materials

Materials designed to reduce environmental impact either by decomposing naturally or being sourced sustainably.

- Polylactic Acid (PLA): A bioplastic made from renewable resources like corn starch or sugarcane. Commonly used in packaging and 3D printing.

- Bamboo Fiber: Bamboo grows rapidly and is a renewable source.

- Mycelium Leather: Derived from fungi, this sustainable material offers an eco-friendly alternative to traditional leather.