Vacuum forming poses hazards such as thermal risks, chemical emissions, electrical dangers, ergonomic challenges, and material handling issues.

Mechanical Hazards

When working with vacuum forming machinery, several mechanical hazards pose risks to operators. Proper understanding and adherence to safety guidelines can significantly mitigate these risks.

Moving Parts and Machinery

Vacuum forming machines have a variety of moving components designed to heat, stretch, and form the plastic sheets. When these components are operational:

- Operators should always be aware of the moving parts to avoid accidental contact.

- It’s crucial to avoid placing hands or other body parts near these moving components, as this can lead to severe injuries.

- Regular maintenance checks can help ensure that the parts move as intended without unexpected jerks or movements.

Machinery Malfunctions

Even the best-maintained machines can occasionally malfunction:

- Having a dedicated technician or maintenance team can ensure timely resolution of any malfunctions.

Thermal Hazards

Vacuum forming relies heavily on the application of heat, which naturally introduces various thermal hazards. Recognizing and understanding these dangers can aid in their prevention, ensuring that operators remain safe during the process.

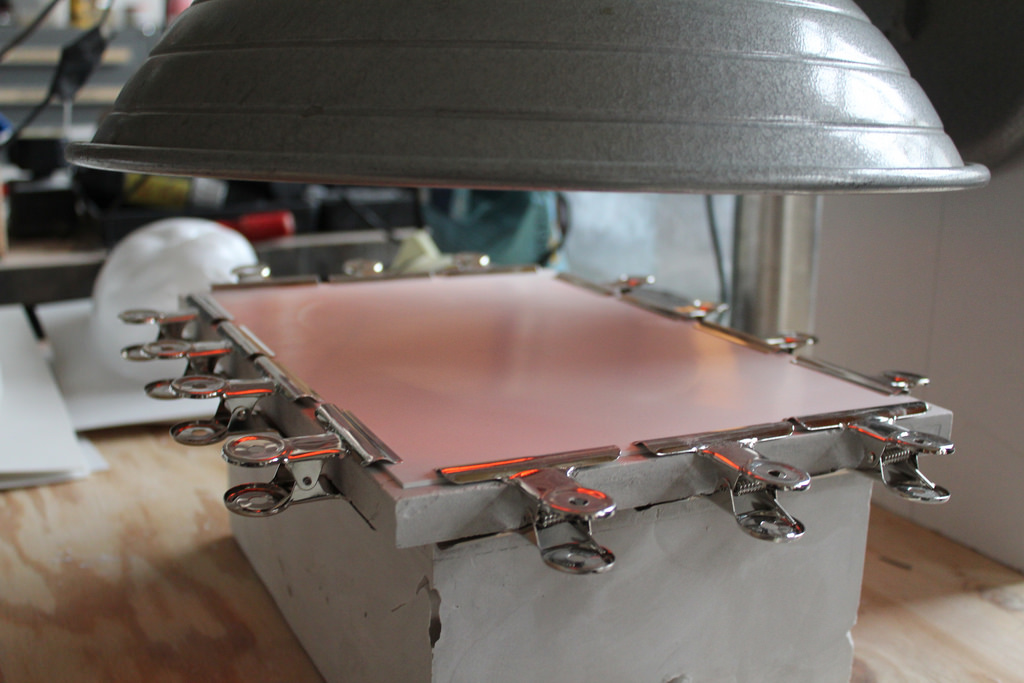

High Temperatures Used in the Process

Vacuum forming demands the heating of plastic sheets until they become malleable, requiring the use of high temperatures:

- Operators must always exercise caution around heaters and heating elements.

- It’s important to wear heat-resistant gloves and protective gear to avoid direct exposure to these elevated temperatures.

- For a deeper understanding of how heat impacts different materials, you might find this Wikipedia article on thermal conductivity enlightening.

Risk of Burns from Hot Surfaces and Materials

Several components and materials get hot during the vacuum forming process:

- Surfaces like heating elements, molds, and even the freshly formed plastic can cause burns upon contact.

- Workers should always be attentive to these hot zones and communicate effectively with team members about potential hot surfaces.

- An understanding of first aid for burns, as discussed on Wikipedia, can be invaluable for immediate response to any accidents.

Proper Handling of Heated Plastic Sheets

Handling heated plastic sheets with care is essential for safety:

- Operators should use appropriate tools and equipment when maneuvering hot sheets to prevent direct contact.

- Sheets should be allowed to cool for a bit before further handling, reducing the risk of burns and deformities in the product.

- The characteristics of plastics when heated can be further explored on Wikipedia.

Chemical Hazards

Vacuum forming, while incredibly versatile, presents certain chemical hazards due to the heating of plastics. Addressing these hazards requires a combination of awareness, preventive measures, and effective response strategies to protect operators and the environment.

Emissions from Heated Plastics

Heating plastics can release various emissions, which might be harmful if inhaled:

- Operators must be aware of the specific types of plastics they are working with and the emissions they produce when heated.

- Some plastics release known carcinogens or irritants, so understanding material properties is crucial.

- Workspaces should be kept clean to minimize the presence of dust and other particulates that can be emitted alongside the fumes.

Potential Toxic Fumes and Vapors

Certain plastics, when heated, emit fumes that can be harmful:

- Acute exposure can lead to symptoms like dizziness, nausea, or respiratory distress.

- Chronic exposure might lead to more severe health problems, such as organ damage or respiratory diseases.

- It’s always good to have a quick reference, such as this Wikipedia article on toxicity, to understand the potential dangers of specific chemicals.

Suitable Ventilation and Respiratory Protection

Minimizing the risks associated with chemical emissions requires proper ventilation and protective equipment:

- Ensure that vacuum forming workspaces have efficient ventilation systems to disperse harmful fumes and vapors.

- Operators should wear appropriate respiratory protection, especially when working with plastics known to emit dangerous chemicals. For more on protective equipment standards, this Wikipedia page on personal protective equipment is a valuable resource.

- Regularly check and maintain ventilation systems to ensure their effectiveness.

Electrical Hazards

Electrical components are intrinsic to the operation of vacuum forming machines. However, these components, if not managed properly, can introduce risks to the operators. Awareness and proactive safety measures can drastically reduce these risks and ensure a safer working environment.

Electrical Components of Vacuum Forming Machines

Every vacuum forming machine is equipped with a variety of electrical components:

- These components range from simple switches to intricate control panels.

- It’s crucial for operators to familiarize themselves with the electrical layout of their specific machine and understand the function of each component.

- Regular inspections can identify wear and tear or potential issues in the electrical circuits. For more insights on electrical components and their functions, this Wikipedia article provides an overview.

Risk of Electrocution or Electrical Fires

Faulty or damaged electrical components pose two primary dangers:

- Electrocution can occur if an operator comes into direct contact with exposed electrical components or wiring.

- Electrical fires can arise from faulty wiring, overloaded circuits, or short circuits. A good resource to understand the causes and prevention of electrical fires is available on Wikipedia.

Proper Grounding and Maintenance

Grounding and regular maintenance are essential to minimizing electrical hazards:

- All machines should be properly grounded to prevent electrical shocks. This grounding ensures that any unexpected electrical surge has a direct path to the earth, reducing the risk of electrocution.

- Maintenance schedules should be strictly adhered to. This involves checking the integrity of wires, ensuring connections are tight, and replacing any worn-out components.

Ergonomic Hazards

The very nature of vacuum forming involves certain tasks and operations that might pose ergonomic challenges. Addressing these issues proactively can help reduce physical strain and injury among operators.

Repetitive Motions during Operation

Consistent and repetitive actions in the vacuum forming process can cause strain:

- Tasks like feeding plastic sheets, adjusting settings, and removing formed parts can become monotonous.

- Over time, these repeated actions can lead to conditions like carpal tunnel syndrome or repetitive strain injury.

- To understand the broader implications of repetitive motions on health, you might consider reading this Wikipedia article on repetitive strain injuries.

Improper Workstation Setup Leading to Strains

The design and setup of the workstation play a significant role in operator comfort:

- Workstations that are too high or too low can lead to back or neck strain.

- Proper ergonomic assessment can help design workstations that align with the natural posture of operators.

Safe Manual Handling Techniques

Lifting and transporting materials or products improperly can cause injuries:

- Operators should be trained on proper lifting techniques, using their legs rather than their backs.

- Utilizing tools and equipment for heavy lifting can also reduce the risk of strain.

Noise and Vibration Hazards

The operation of vacuum forming machines can lead to significant noise and vibrations, which can have detrimental effects on operators if not managed appropriately.

High Levels of Noise from Machinery

Vacuum forming machines can be quite loud:

- Prolonged exposure to this noise can lead to stress and even hearing impairment.

- It’s crucial to provide soundproofing where possible and ensure operators have ear protection.

Potential for Hearing Loss

Continuous exposure to loud noises can damage hearing:

- Ear protection, such as earmuffs or earplugs, can help reduce the risk of hearing loss.

- Regular hearing tests and checks for operators can help in early detection and intervention.

Vibration Hazards and Their Impact

Machines produce vibrations which, over time, can impact operators:

- Hand-arm vibration syndrome can be a result of prolonged exposure to vibrating machinery.

- Anti-vibration gloves and mats can help in reducing the impact of vibrations.

Material Handling Hazards

In the vacuum forming industry, material handling is an integral aspect of the process. Proper precautions and techniques can help avoid accidents and enhance safety.

Safe Storage of Raw Materials and Finished Products

Effective storage methods are paramount:

- Shelves and racks should be stable and robust to prevent collapse.

- Proper labeling and segregation can prevent mix-ups and contamination.

Risk of Cuts from Sharp Edges on Formed Products

Formed plastic products can often have sharp edges:

- Operators should be trained to handle these products with caution, using gloves if necessary.

- Deburring or edge-smoothing processes can be introduced to reduce the sharpness of products.

Safe Transportation Methods

Moving materials and products safely is crucial:

- Use of trolleys, forklifts, or other transportation equipment should be encouraged for heavy items.

- Aisles and pathways should be kept clear to prevent tripping hazards.

Safety Protocols and Training

Safety is a continuous endeavor and requires constant reinforcement through training and protocols.

Importance of Regular Training

Consistent training is key:

- Training sessions should be conducted periodically to refresh safety measures and introduce any new protocols.

- New employees should undergo a mandatory safety orientation.

Safety Equipment and Its Proper Use

Protective gear is essential:

- Equipment like gloves, goggles, ear protection, and face masks should be provided based on the task.

- Regular checks to ensure the proper condition of this equipment is vital.

- For a broader view on safety equipment, consider reading Wikipedia.