Extrusion in food processing involves techniques like cold extrusion, hot extrusion, and twin-screw extrusion.

Introduction

Extrusion has emerged as a versatile and indispensable method in food processing. The technique, which forces raw ingredients through a shaping orifice, has been around for ages and has adapted over time. This ability to mold and shape materials, especially food, has made it a favorite for product innovation and development.

Definition of Extrusion

Extrusion is a process where a set of mixed ingredients are forced through an opening in a perforated plate or die to produce a product with a specific cross-sectional shape. Think of it like squeezing toothpaste out of a tube. The design of the die and the conditions under which extrusion occurs can significantly influence the texture, shape, and properties of the final product. If you’re curious about its depth, Wikipedia provides a broader perspective on this technique, beyond just its application in food processing.

Historical Background of Food Extrusion

The use of extrusion in food dates back to ancient civilizations. In its nascent stages, extrusion was manually executed, with dough being pressed through molds to create specific shapes. The industrial revolution ushered in more advanced and mechanized methods of extrusion. By the mid-20th century, the introduction of screw extruders transformed the way food was processed, leading to the production of a wide variety of products, from breakfast cereals to ready-to-eat snacks. A notable leap in the history of food extrusion was the development of twin-screw extruders in the 1970s, offering better mixing capability and control over the process. The evolution of this technology, combined with a better understanding of food science, paved the way for an array of products with varied textures, sizes, and nutritional profiles. For a more exhaustive historical journey, the Wikipedia page on Food Extrusion is an excellent resource.

Types of Extruders

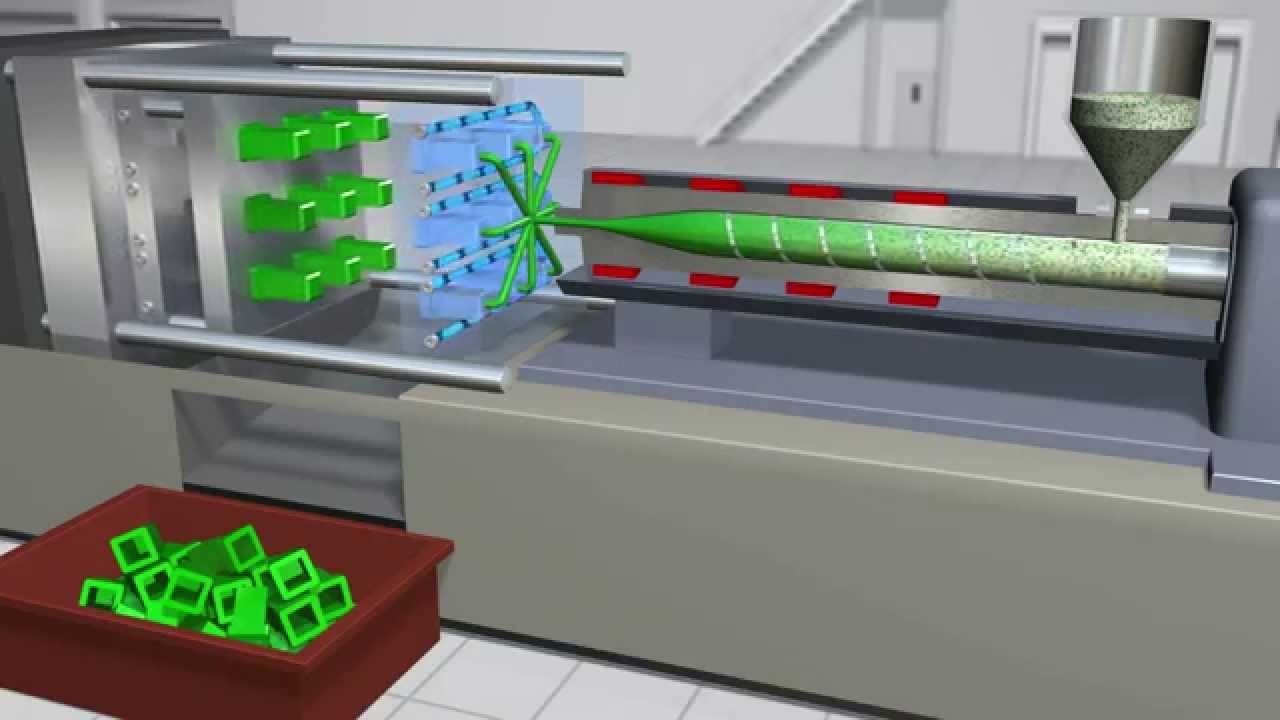

Extruders play a pivotal role in determining the quality, texture, and nutritional value of food products. Choosing the right type of extruder is essential for achieving the desired product characteristics while maintaining efficiency and cost-effectiveness. There are primarily three types of extruders in the food industry: Single Screw, Twin Screw, and Piston Extruders.

Single Screw Extruders

Single screw extruders, as the name suggests, utilize a single rotating screw within a stationary barrel to process the raw materials. These extruders are known for their simplicity and are typically more affordable, with prices starting from $20,000 for basic models. With a power range between 50 to 250 kW, they are commonly used for producing pasta, snacks, and some cereal products.

Advantages:

- Cost-effective for small to medium scale production.

- Simpler design makes maintenance easier.

Disadvantages:

- Limited mixing capability can lead to inconsistent product quality.

- Lower efficiency in handling multiple or complex ingredients.

Twin Screw Extruders

Twin Screw Extruders use two intertwined screws, allowing for more intense mixing and shearing of ingredients. They can operate at a higher power, ranging from 100 to 500 kW, which can lead to faster processing speeds. Their starting price is around $50,000 but can go up substantially based on specifications and additional features.

Advantages:

- Superior mixing capability, ensuring even distribution of ingredients.

- Can handle a diverse range of raw materials, from high protein to high fiber.

Disadvantages:

- Higher initial cost.

- More complex design can lead to higher maintenance costs.

For a deep dive, you might want to check out the Twin Screw Extruders Wikipedia page.

Piston Extruders

Piston extruders, less common in the food industry, use a piston to push the material through the die. They are particularly effective for certain specialized products that require specific textural qualities. The average price for a piston extruder starts at around $30,000.

Advantages:

- Precise control over the extrusion process.

- Suitable for specific products with unique texture requirements.

Disadvantages:

- Not as versatile as screw extruders.

- Might not be efficient for large-scale production.

Extrusion Process Parameters

In the world of food processing, extrusion stands as a vital technique. To achieve the desired food product with the right taste, texture, and nutritional value, one must meticulously control various extrusion process parameters. Each parameter directly impacts the efficiency, cost, and quality of the end product.

Temperature Control

Temperature plays a crucial role in determining the texture, color, and nutritional quality of the extruded product. A typical extruder can operate within a temperature range of 100°C to 200°C.

Advantages:

- Proper temperature ensures the gelatinization of starch, leading to a desirable texture.

- Helps in the Maillard reaction, which gives specific products their characteristic brown color and flavor.

Disadvantages:

- Excessive temperature can degrade essential nutrients and lead to an undesirable product.

- High temperatures increase energy costs. For instance, every 10°C increase can elevate energy costs by approximately 3%.

For more on temperature’s role in extrusion, consult the detailed Wikipedia article on Extrusion.

Screw Speed

The rotational speed of the screw, measured in RPM (revolutions per minute), affects the shear rate and consequently, the amount of heat generated during the extrusion process. A typical range for screw speed is 100 to 1500 RPM.

Advantages:

- Faster screw speeds can produce higher outputs, optimizing production time.

- Enables better mixing and homogenization of ingredients.

Disadvantages:

- Very high speeds might lead to uneven cooking and potential degradation of the product.

- Increases wear and tear on the extruder, possibly leading to higher maintenance costs.

Read more on the importance of screw speed in the Wikipedia’s Extrusion section.

Feed Rate and Moisture Content

The rate at which raw materials are fed into the extruder and their moisture content directly impact product quality. Feed rates can vary from 100 to 2000 kg/h, while the ideal moisture content typically ranges from 10% to 30%.

Advantages:

- Proper feed rate ensures consistent product quality.

- Adequate moisture content aids in the cooking process and texture formation.

Disadvantages:

- Inconsistent feed rates can lead to variations in product quality.

- Too much moisture might result in a soggy product, while too little can make it overly dry.

The relationship between feed rate and moisture content in extrusion is elaborated in this Wikipedia section.

Die Design and Shape

The die, through which the material is extruded, governs the shape and size of the final product. Dies can range in size from 1mm to 50mm, depending on the desired product.

Advantages:

- Enables the production of diverse products, from thin noodles to thick tubular snacks.

- Proper die design ensures consistent product shape and size.

Disadvantages:

- A poorly designed die can lead to product defects, like cracks or irregular shapes.

- Changing dies can be time-consuming and disrupt the production flow.

Materials Used in Extrusion

Extrusion is a versatile technique, allowing for a wide array of materials to be processed. The choice of material is pivotal, as it directly influences the texture, nutritional profile, and overall appeal of the final product. From traditional cereals to innovative hydrocolloids, a myriad of ingredients undergo extrusion to create diverse food products.

Cereals and Grains

Cereals and grains form the backbone of many extruded products, such as breakfast cereals, snacks, and pasta. Popular grains used include wheat, rice, maize, barley, and oats.

Advantages:

- Rich in carbohydrates, providing energy.

- Can achieve a wide range of textures, from crispy to soft, depending on the extrusion conditions.

Disadvantages:

- May lack certain essential amino acids, necessitating combinations with other protein sources.

- Some grains, like wheat, contain gluten, which can be allergenic to certain individuals.

Cost: On average, bulk purchasing of cereals like wheat can range from $200 to $400 per ton, depending on the market conditions.

For a deeper insight into the world of cereals, check out the Wikipedia page on Cereals.

Proteins

Proteins, derived from both animal and plant sources, are increasingly processed through extrusion, especially with the rise of vegetarian and vegan diets. Common protein sources include soy, peas, lentils, and even dairy.

Advantages:

- Offers a balanced amino acid profile, essential for muscle growth and repair.

- Provides a meat-like texture, suitable for creating meat analogues or vegetarian meat replacements.

Disadvantages:

- Some protein sources, especially soy, can have a beany or off-flavor which needs to be masked.

- The cost of protein-rich raw materials can be significantly higher than cereals.

Cost: Soy protein concentrates, commonly used in extrusion, can be priced between $800 to $1200 per ton.

The vast domain of proteins in food can be further explored on Wikipedia’s Protein page.

Starches and Hydrocolloids

Starches and hydrocolloids act as binders and texture enhancers in extruded products. Commonly used starches include cornstarch, tapioca, and potato starch, while popular hydrocolloids encompass guar gum, xanthan gum, and alginate.

Advantages:

- Imparts a gel-like consistency, helping in moisture retention.

- Enhances the mouthfeel of the product.

Disadvantages:

- Overuse can result in a product that’s too sticky or gummy.

- Certain hydrocolloids can be expensive.

Applications of Food Extrusion

Extrusion technology has paved the way for a variety of food products that grace supermarket shelves today. Its versatility has fostered innovation in the food industry, meeting both traditional and contemporary consumer demands. From the crispy cereals we enjoy in the mornings to meat substitutes preferred by vegans, the applications of food extrusion span widely.

Breakfast Cereals

A staple in many households, breakfast cereals undergo extrusion to achieve their distinct shapes, textures, and flavors.

Advantages:

- Quick and convenient breakfast option.

- Can be fortified with essential vitamins and minerals.

Disadvantages:

- Some may contain high sugar levels, posing health concerns.

- Over-processing might strip away natural nutrients.

Market Value: The global breakfast cereal market was valued at approximately $40 billion in 2020.

For more insights into breakfast cereals and their popularity, refer to the Wikipedia page on Breakfast Cereals.

Snack Foods

From cheese puffs to grain-based bars, extrusion plays a pivotal role in creating an array of snack foods.

Advantages:

- Offers diverse flavors and textures.

- Suitable for on-the-go consumption.

Disadvantages:

- Might contain high levels of salt and unhealthy fats.

- Over-reliance can lead to nutritional imbalances.

Cost to produce: Producing extruded snacks can cost anywhere between $1 to $5 per kilogram, based on ingredients and processing techniques.

Delve deeper into the vast universe of snacks on Wikipedia’s Snack page.

Pasta and Noodles

Extrusion ensures that pasta and noodles have the desired consistency, shape, and cooking qualities.

Advantages:

- Versatile in terms of shapes and sizes.

- Can be enriched with proteins or fibers for enhanced nutrition.

Disadvantages:

- Some varieties might have a high glycemic index.

- Overcooking can make them mushy.

Average Price: A kilogram of extruded pasta can range from $2 to $10, depending on the brand and ingredient quality.

Meat Analogues

With the rise of veganism and vegetarianism, meat analogues or substitutes made from plant proteins have gained traction, and extrusion facilitates their texture and taste.

Advantages:

- Provides a similar texture to meat, catering to vegetarians and vegans.

- Often lower in saturated fats compared to real meat.

Disadvantages:

- Some might lack the complete protein profile of real meat.

- Flavor matching can be challenging.

Cost of Production: Producing a kilogram of meat analogue can range between $6 to $12, depending on the raw materials and processing.

Explore the growing world of meat substitutes on Wikipedia’s Meat Analogue page.

Functional Foods and Nutraceuticals

These are foods fortified with additional nutrients or bioactive compounds that provide health benefits. Extrusion allows for the encapsulation and protection of these compounds.

Advantages:

- Offers added health benefits beyond basic nutrition.

- Suitable for targeting specific health concerns.

Disadvantages:

- Overconsumption might lead to excessive intake of certain nutrients.

- Some bioactive compounds might degrade during processing.

Market Value: The global functional foods market was estimated to be worth around $170 billion in 2020.

Quality and Nutritional Aspects

Extrusion, while being a versatile and innovative technique, also profoundly impacts the quality and nutritional profile of food products. It can both enhance certain qualities, such as texture, and at times pose challenges, like nutrient degradation. As consumers become more discerning about their food choices, understanding the implications of extrusion on quality and nutrition becomes paramount.

Texture and Physical Properties

Texture is one of the primary sensory attributes that dictates consumer preference. Extrusion, by altering the molecular structure of food components, especially starches and proteins, defines the final texture of the product.

Advantages:

- Enables the production of a wide range of textures from crispy snacks to soft pasta.

- Allows for uniform and consistent products, enhancing consumer acceptability.

Disadvantages:

- Over-extrusion or incorrect parameters can lead to undesirable textures, such as toughness or sogginess.

- Textural attributes might change over time, especially in the presence of moisture.

Research Findings: Studies have shown that a screw speed of 250 rpm often yields optimal crispiness in corn-based snacks.

Dive deeper into the science of food texture with the Wikipedia page on Food Rheology.

Nutrient Retention and Degradation

The high temperatures and shear forces involved in extrusion can influence the stability of certain nutrients, leading to either their retention or degradation.

Advantages:

- Can enhance the bioavailability of certain nutrients, making them easier to absorb.

- Phytochemicals and antioxidants might see an increase post-extrusion due to cell wall breakdown.

Disadvantages:

- Heat-sensitive vitamins, such as vitamin C, might degrade during the process.

- Over-processing can strip away essential nutrients, leading to a nutritionally inferior product.

Fact Check: Vitamin C can degrade by up to 50% during the extrusion of certain food products, necessitating post-extrusion fortification.

For more insights on nutrient stability, refer to Wikipedia’s page on Nutrient Retention.

Flavor and Aroma Development

Flavor, a combination of taste and aroma, is a complex trait heavily influenced by extrusion. The Maillard reaction, which occurs during extrusion, plays a significant role in flavor development.

Advantages:

- Generates rich and complex flavors, especially in products like toasted cereals and roasted snacks.

- Enables the infusion of flavors post-extrusion, leading to diverse taste profiles.

Disadvantages:

- Unwanted flavors might develop if parameters are not optimized.

- Certain aromatic compounds might evaporate, leading to diminished flavor intensity.

Cost Implication: Incorporating high-quality flavor enhancers post-extrusion can increase production costs by 10-15%.