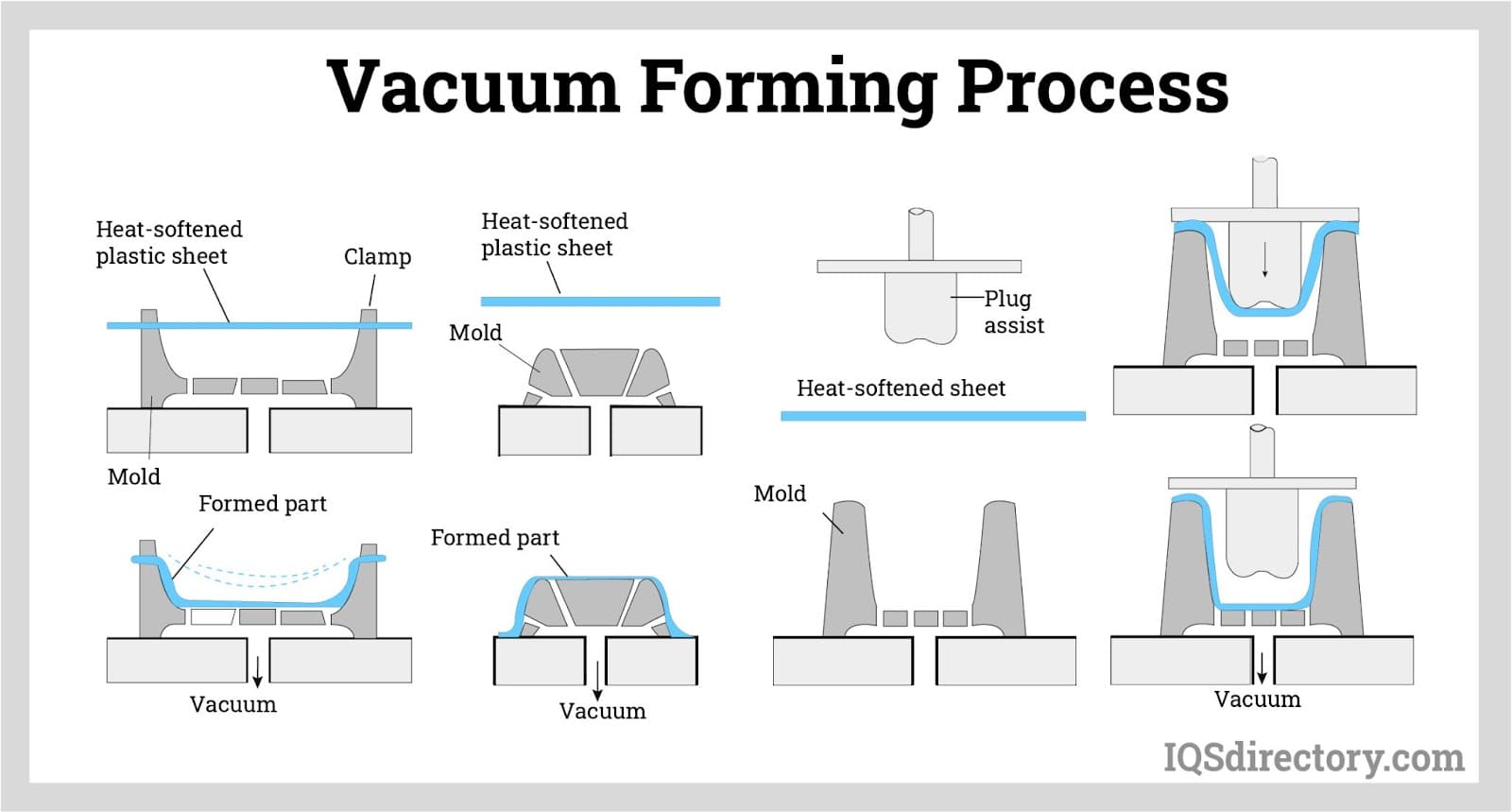

Vacuum forming types include single-sheet, double-sheet, snap-back, drape forming, and pressure bubble plug assist forming.

Basic Principles of Vacuum Forming

The Process of Vacuum Forming

Vacuum forming, often referred to as thermoforming, is a process where a sheet of plastic is heated to a formable temperature, stretched onto or into a mold, and held against the mold by applying a vacuum between the mold surface and the sheet. Here’s a step-by-step breakdown:

Choosing the Right Mold

Selecting the appropriate mold is crucial. Molds can be made from various materials, including wood, aluminum, and resin. The choice depends on factors like the desired shape, intricacy, and number of productions.

Heating the Plastic Sheet

The plastic sheet, often made from materials like polystyrene or PET, is first heated in an oven until it reaches a soft and pliable state. The optimal temperature varies but for polystyrene, it’s typically around 150°C to 180°C.

Forming the Shape

Once heated, the pliable plastic sheet is placed over the mold. A vacuum is then applied, drawing the sheet tightly around or into the mold, ensuring every detail is captured. This process usually lasts between 20 to 60 seconds.

Cooling and Release

After the desired shape is achieved, the formed plastic is allowed to cool, hardening into its final shape. The cooling time can range from a couple of minutes up to 10 minutes, depending on the thickness and type of plastic. Once cooled, the vacuum is released, and the formed plastic part is removed from the mold.

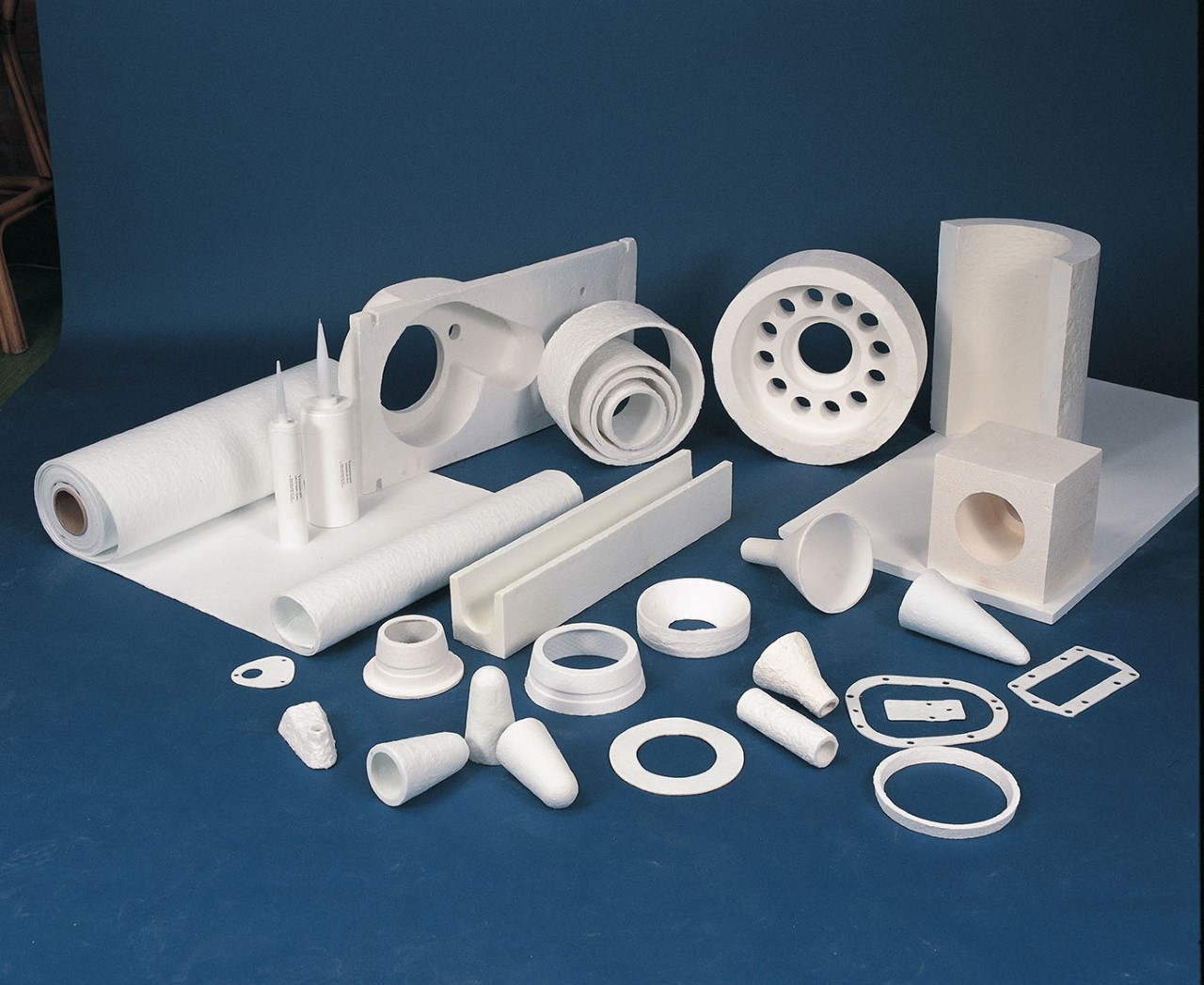

Materials Used in Vacuum Forming

Different materials offer varying properties, such as flexibility, strength, clarity, and resistance to UV rays or chemicals.

Polystyrene (PS)

Polystyrene is one of the most common materials used in vacuum forming. A standard sheet might cost around $20 per square meter.

Polyethylene Terephthalate (PET)

PET is renowned for its clarity and strength. It’s recyclable, making it an eco-friendly choice. Commonly used for food packaging, its cost is slightly higher than polystyrene, with prices ranging from $25 to $35 per square meter.

Acrylic (PMMA)

It has excellent weathering properties, making it suitable for outdoor applications.

Polyvinyl Chloride (PVC)

PVC is versatile, known for its resistance to chemicals and oils. Depending on the grade and specifications, the price can range from $30 to $45 per square meter.

Types of Vacuum Forming

Single-sheet Vacuum Forming

Single-sheet vacuum forming is one of the most common types of vacuum forming processes. In this method:

- A single sheet of plastic material is used.

- The plastic sheet is heated until it becomes malleable.

- The sheet is then stretched over a mold, and a vacuum is applied to pull the sheet onto the mold’s shape.

- Ideal for making simple parts like trays or blister packaging.

- Provides a cost-effective solution for medium to large production runs.

- Examples of use include toy packaging and cosmetic trays.

Double-sheet Vacuum Forming

As the name suggests, this method involves:

- Using two sheets of plastic simultaneously.

- These sheets are heated and then formed over and under the mold.

- It results in a product that has a formed surface on both sides.

- Typically used for making more robust and detailed parts.

- Examples include double-sided signs or hollow objects.

Vacuum Snap-back Forming

This specialized method involves:

- Heating the plastic sheet beyond its typical forming temperature.

- Placing the overly softened sheet above a mold.

- The vacuum then pulls the sheet down, and as it cools slightly, it snaps back, taking the shape of the mold.

- It allows for more intricate details and sharper corners.

- It’s perfect for parts that require detailed textures or logos, such as automotive components.

Drape Forming

Drape forming is a simpler form of vacuum forming. Here:

- The heated plastic sheet drapes or sags onto a mold due to gravity and external force.

- A vacuum is then applied to ensure a tight fit around the mold.

- This method is often used for larger parts that don’t require intricate detailing.

- Examples include bathtub liners or large panels.

Pressure Bubble Plug Assist Forming

This advanced method:

- Combines the use of pressure and vacuum to form the plastic sheet.

- Initially, a bubble of air (pressure bubble) is introduced, pushing the heated plastic sheet upward.

- A plug then pushes the bulging sheet down into the mold.

- The vacuum ensures the sheet adheres to every detail of the mold.

- It’s suitable for deep-draw parts or those with uneven wall thicknesses.

- Examples of its application include deep yogurt cups or containers with a pronounced depth.

Applications of Different Vacuum Forming Types

Packaging Industry

Vacuum forming plays a vital role in the packaging industry. The reasons for its popularity include:

- Cost-Effectiveness: Producing large quantities becomes economical.

- Customization: Can be tailored to fit specific products perfectly.

- Visibility: Transparent plastics like PET showcase the product inside.

- Examples:

- Blister packaging for medications.

- Clamshell packaging for electronics or toys.

- Food trays for ready meals.

Automotive Parts

The automotive industry utilizes vacuum forming for a variety of components:

- Lightweight: Helps in reducing the overall weight of vehicles.

- Durability: Parts made are resistant to wear and tear, crucial for vehicles.

- Aesthetics: Allows for creating visually appealing components with intricate designs.

- Examples:

- Dashboard components.

- Interior panels and linings.

- Car bumpers and fenders.

Medical Equipment

Vacuum forming has become integral in the production of medical equipment due to:

- Hygienic: The seamless design reduces areas where bacteria can thrive.

- Customization: Can be tailored to specific medical applications.

- Safety: Materials used are often bio-compatible and non-reactive.

- Examples:

- Dental retainers and mouth guards.

- Trays for surgical instruments.

- Prosthetic device covers.

Consumer Products

Everyday items often benefit from the versatility of vacuum forming:

- Flexibility: Suitable for a vast range of products from household items to recreational gear.

- Economical Production: Producing large batches becomes cost-effective.

- Quality Finish: Offers a polished and high-quality appearance to products.

- Examples:

- Storage containers and organizers.

- Children’s toys and playsets.

- Helmet shells for sports and recreation.

Comparison with Other Forming Processes

Vacuum Forming vs. Injection Molding

Both vacuum forming and injection molding are popular methods for producing plastic parts, but they have distinct differences:

- Process:

- Vacuum Forming: Involves heating a plastic sheet and using a vacuum to form it over a mold.

- Injection Molding: Molten plastic is injected into a mold under high pressure.

- Material Usage:

- Vacuum Forming: Typically uses thermoplastic sheets.

- Injection Molding: Utilizes thermoplastic or thermosetting polymers.

- Production Speed:

- Vacuum Forming: Generally quicker for smaller production runs.

- Injection Molding: More suitable for large-scale production due to the fast cycle times once the mold is created.

- Cost:

- Vacuum Forming: Lower initial costs, especially for prototype development or small batches.

- Injection Molding: High initial setup costs but per-unit cost becomes low for large quantities.

- Applications:

- Vacuum Forming: Ideal for larger parts, packaging, and panels.

- Injection Molding: Common for small to medium-sized complex parts like buttons, housings, and gears.

- Flexibility:

- Vacuum Forming: More flexible in terms of design changes, especially during the prototype phase.

- Injection Molding: Design changes can be costly due to the mold’s complexity and price.

Vacuum Forming vs. Blow Molding

Vacuum forming and blow molding both shape plastics, but their techniques and applications differ:

- Process:

- Vacuum Forming: Heats a plastic sheet which is then formed over a mold using a vacuum.

- Blow Molding: Involves inflating a heated plastic tube (parison) inside a mold to take its shape.

- Material Usage:

- Vacuum Forming: Typically thermoplastic sheets.

- Blow Molding: Mainly uses thermoplastic materials like HDPE, PVC, and PET.

- Production Speed:

- Vacuum Forming: Suitable for both short and medium production runs.

- Blow Molding: Ideal for large-scale production.

- Cost:

- Vacuum Forming: Lower mold costs and suitable for cost-effective prototypes.

- Blow Molding: Lower per-unit cost for mass production but higher mold costs.

- Applications:

- Vacuum Forming: Panels, packaging, and larger parts with shallow depths.

- Blow Molding: Primarily for producing hollow objects like bottles, containers, and tanks.

- Design Flexibility:

- Vacuum Forming: Adaptable to design changes without massive costs.

- Blow Molding: Design changes can be pricier and more complex due to the intricacies of the mol