To design for injection molding, consider material properties, mold design, process parameters, and part functionality.

Design Considerations for Injection Molding

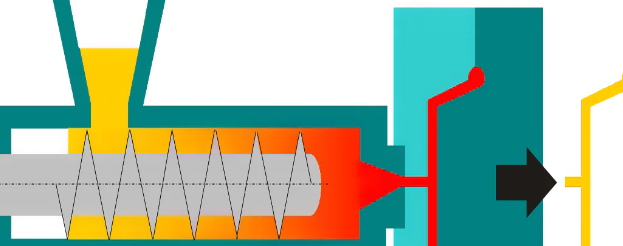

Injection molding is a versatile and widely used manufacturing process for producing complex plastic parts with high efficiency and precision. Understanding the key design considerations is crucial for successful production.

Material Selection and Properties

- Thermoplastic Varieties: Select appropriate thermoplastics like ABS, Polyethylene, or Nylon based on the part’s intended use. Each material has distinct characteristics like heat resistance, strength, and flexibility.

- Physical and Chemical Properties: Consider the impact strength, tensile strength, and melting point of the material. For example, Polycarbonate offers high impact resistance, making it ideal for protective gear.

- Environmental Factors: Choose materials with UV resistance or moisture barrier properties if the product will be exposed to harsh environmental conditions.

Designing for Manufacturing Efficiency

- Minimize Wall Thickness: Design parts with uniform wall thickness to ensure even cooling and reduce warping. The ideal thickness typically ranges between 1.5 mm and 3 mm.

- Incorporate Draft Angles: Include a draft angle of 1 to 2 degrees on vertical walls to facilitate easy ejection from the mold.

- Simplify Design: Avoid unnecessary complexity in design. Simple designs often result in more efficient manufacturing and lower costs.

Balancing Aesthetics and Functionality

- Surface Finish: Determine the type of surface finish needed, like matte, glossy, or textured. This affects both the appearance and functionality of the part.

- Color Considerations: Choose colors that align with brand identity and customer appeal. Use pigments that are compatible with the chosen material.

- Functional Aesthetics: Design parts that are not only visually appealing but also ergonomic and user-friendly, enhancing the overall user experience.

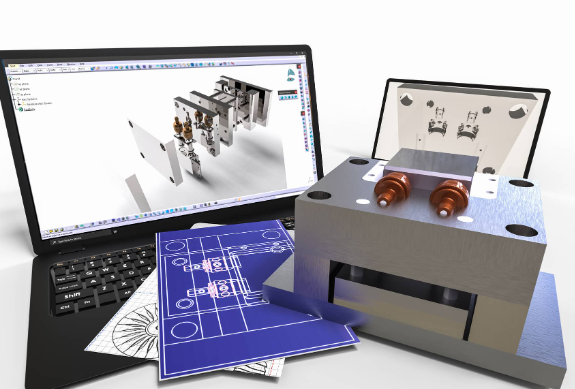

Mold Design and Construction

The design and construction of molds are crucial in injection molding, significantly impacting the quality, efficiency, and lifecycle of the produced parts.

Types of Molds in Injection Molding

- Two-Plate Molds: These are the simplest and most common molds, consisting of two plates that allow for easy ejection of the molded part.

- Three-Plate Molds: More complex, these molds allow for automatic ejection and are used for parts requiring more intricate gating systems.

- Stack Molds: Ideal for mass production, stack molds multiply the production capacity of a single molding machine by employing multiple mold parting surfaces.

Key Features of Effective Molds

- Robust Material Selection: Use hardened steel or aluminum for mold construction to ensure durability and longevity. Hardened steel molds can withstand up to a million cycles, while aluminum molds are more cost-effective but less durable.

- Precision Machining: Ensure high-precision machining for the molds to achieve the desired tolerances, which can be as tight as ±0.01 mm.

- Efficient Cooling System: Design an effective cooling system to reduce cycle time and prevent defects. Proper cooling can reduce cycle time by up to 30%.

Mold Maintenance and Care

- Regular Cleaning: Regularly clean the molds to prevent the buildup of residues and ensure the quality of the parts produced.

- Lubrication: Lubricate moving parts to reduce wear and tear. This extends the mold’s lifespan and maintains its operational efficiency.

- Periodic Inspection: Conduct frequent inspections for wear and damage, especially for high-volume production molds. Early detection of issues can prevent costly repairs and downtime.

Mold Design and Construction

This process involves several key elements, from selecting the right type of mold to implementing features that enhance functionality and longevity.

Types of Molds in Injection Molding

- Two-Plate Molds: These are commonly used for simpler parts. They consist of two halves: the cavity side and the core side, which separate to release the finished part.

- Three-Plate Molds: Suitable for more complex parts, these molds have an additional plate to allow more flexibility in gate placement and automatic part ejection.

- Stack Molds: They are ideal for high-volume production, doubling or tripling the output without increasing the machine size. These molds have multiple levels of cavities for simultaneous part production.

Key Features of Effective Molds

- Robust Material Construction: Using high-grade steel or aluminum for durability, with steel offering a longer lifespan.

- Precision Engineering: Ensuring tight tolerances for accurate part dimensions, which is essential for complex or interlocking parts.

- Efficient Cooling Channels: Designing cooling channels effectively to reduce cycle time and prevent defects like warping or shrinkage.

Mold Maintenance and Care

- Regular Cleaning: Keeping the mold clean to avoid residue buildup that could affect part quality.

- Routine Lubrication: Ensuring that moving parts, like ejector pins, are lubricated to prevent wear and maintain smooth operation.

- Inspection and Repairs: Conducting regular inspections for wear or damage and undertaking prompt repairs to prolong the mold’s life and ensure consistent quality.

Optimizing the Injection Molding Process

Optimizing the injection molding process is essential for enhancing efficiency, quality, and cost-effectiveness. Key areas of focus include controlling temperature and pressure, ensuring consistent quality, and reducing cycle time and costs.

Controlling Temperature and Pressure

- Precise Temperature Control: Maintain optimal material temperature for fluidity and solidification. For instance, ABS requires a temperature range of 200-250°C.

- Consistent Pressure Application: Apply uniform pressure to ensure complete cavity filling and reduce defects. The pressure range varies based on material and part design but typically lies between 500 to 1500 bar.

- Monitoring and Adjustments: Use sensors and control systems to monitor temperature and pressure continuously, making real-time adjustments as necessary.

Ensuring Consistent Quality

- Stringent Quality Checks: Implement regular quality inspections, using methods like dimensional checks and strength testing to ensure each part meets specifications.

- Process Consistency: Maintain consistent cycle times, material feed rates, and environmental conditions to reduce variability in part quality.

- Feedback Loop: Establish a feedback loop to incorporate insights from quality checks back into the process, enhancing future production runs.

Reducing Cycle Time and Costs

- Efficient Mold Design: Design molds with optimal cooling channels and efficient ejection mechanisms to minimize cycle time.

- Material Optimization: Use materials that solidify at the right speed and temperature to reduce cooling time. For instance, Polypropylene cools faster than many other thermoplastics.

- Process Automation: Implement automation in areas like material handling and part removal to speed up the process and reduce labor costs.

Advanced Techniques in Injection Molding

Injection molding continues to evolve with the integration of advanced techniques that enhance the capabilities and efficiency of the manufacturing process. These advancements include multi-material molding, the integration of automation and robotics, and innovations in mold design.

Utilizing Multi-material Molding

- Overmolding: This technique involves molding a second material over a previously molded part, ideal for creating parts with soft grips or dual-textured surfaces.

- Co-Injection Molding: Injecting two different materials simultaneously to create a single part with unique properties, such as a rigid core and a soft exterior.

- Material Compatibility: Select materials that bond well and meet the functional requirements of the final product. For example, TPE overmolded onto PP creates durable, ergonomic tool handles.

Integrating Automation and Robotics

- Robotic Part Handling: Employ robots for tasks like part removal and assembly to increase speed and reduce manual labor costs.

- Automated Quality Control: Implement automated systems for in-line quality checks, such as vision systems for dimensional accuracy and defect detection.

- Process Optimization: Use automation to optimize cycle times and process parameters, leading to increased overall efficiency and throughput.

Innovations in Mold Design

- 3D Printed Molds: Utilize 3D printing for rapid prototyping or producing complex mold designs that are challenging to achieve with traditional machining.

- Advanced Cooling Systems: Implement conformal cooling channels that closely follow the part’s geometry, resulting in more uniform cooling and reduced cycle times.

- Smart Molds: Incorporate sensors and IoT technology into molds to monitor conditions like temperature and pressure in real-time, allowing for dynamic adjustments and predictive maintenance.

Case Studies and Real-world Applications

Exploring case studies and real-world applications provides valuable insights into the practical aspects of injection molding, revealing how different industries utilize this technology for innovative solutions.

Success Stories in Various Industries

- Automotive Industry: The use of injection molding for producing complex, lightweight car components like dashboards and bumpers has significantly improved fuel efficiency.

- Medical Sector: Injection molding is pivotal in manufacturing sterile, high-precision medical devices such as syringes and surgical tools, where accuracy is paramount.

- Consumer Electronics: The production of durable and aesthetically pleasing parts for devices like smartphones and laptops showcases the versatility of injection molding in handling different materials and finishes.

Lessons Learned from Complex Projects

- Material Selection: Choosing the right material for a project can drastically affect functionality and cost. For instance, selecting a high-performance polymer can increase the lifespan of a part but also raise the manufacturing costs.

- Design for Manufacturability: Complex projects often highlight the importance of designing parts that are not only functional but also easy to manufacture, balancing aesthetics with practicality.

- Efficiency in Production: Streamlining the injection molding process, like optimizing cycle times and reducing waste, can lead to significant cost savings without compromising quality.

Future Trends and Directions

- Sustainability: Increasing focus on environmentally friendly materials and practices, such as biodegradable plastics and recycling initiatives.

- Smart Manufacturing: Integration of Industry 4.0 technologies like AI and IoT for real-time monitoring and process optimization in injection molding.

- Customization and Personalization: Advancements in mold design and manufacturing techniques are enabling more bespoke solutions, catering to the growing demand for personalized products.