Yes, thermosetting plastics can be vacuum formed, but it requires careful control due to their non-remelting nature after curing.

Properties of Thermosetting Plastics

Thermosetting plastics, often contrasted with thermoplastics, are a unique category of polymers that solidify or “set” irreversibly when heated. This property makes them indispensable for certain applications where high thermal stability and structural rigidity are required. Let’s delve into their chemical properties and the different types available in the market.

Chemical Structure and Characteristics

- Cross-Linked Structure: At the molecular level, thermosetting plastics exhibit a cross-linked structure. This means that the polymer chains are interconnected, providing them with stability and resistance against melting upon reheating.

- Curing Process: Unlike thermoplastics which can be repeatedly melted and solidified, thermosets undergo a curing process. This is a one-time, irreversible process that gives the plastic its final shape.

- Thermal Stability: Due to their unique structure, thermosets demonstrate high thermal stability. They don’t melt upon reheating, but instead degrade or decompose.

- Electrical Properties: These plastics are generally good electrical insulators, making them suitable for electrical components that need to withstand high temperatures.

Types of Thermosetting Plastics and their Applications

- Epoxy Resins: Often used in adhesives, coatings, and composite materials. Epoxy resins have excellent adhesive properties and chemical resistance.

- Melamine Formaldehyde (MF): Commonly used for laminates and decorative surfaces due to its hard, glossy finish.

- Phenol Formaldehyde (PF): One of the oldest synthetic polymers, it’s mainly used in the production of circuit boards and as binders in wood products.

- Urea Formaldehyde (UF): Predominantly used in adhesives, particle boards, and molded objects. It’s known for its excellent dimensional stability and bonding capabilities.

- Polyester Resins: Typically utilized in the making of boat hulls, automotive bodies, and fiberglass materials. They offer good resistance to environmental conditions.

Vacuum Forming Process

The vacuum forming process, a subset of thermoforming, involves heating a plastic sheet to a moldable state and then shaping it using a mold and vacuum. The procedure has widespread applications, from product packaging to automotive components. Let’s understand the foundational principles, ideal materials, and both the advantages and drawbacks of this method.

Fundamental Principles of Vacuum Forming

- Heating the Plastic Sheet: The initial step entails heating a plastic sheet until it becomes pliable. This softening allows for easy molding.

- Molding with a Form: Once softened, workers place the plastic sheet over a mold or form. The form represents the final desired shape.

- Applying Vacuum: A vacuum source removes the air between the mold and the plastic sheet. This action causes the plastic to snugly fit onto the mold, capturing even intricate details.

- Cooling and Solidification: After achieving the desired shape, the plastic cools and solidifies, retaining the mold’s shape. Once cooled, manufacturers trim the excess plastic to finalize the product.

Suitable Materials for Vacuum Forming

- Polystyrene (PS): A versatile and commonly used material in vacuum forming, often found in product packaging and disposable items.

- Acrylonitrile Butadiene Styrene (ABS): With a blend of strength and flexibility, ABS is ideal for automotive parts and protective gear.

- Polyvinyl Chloride (PVC): Used in everything from blister packs to piping, PVC offers chemical resistance and flexibility.

- Polymethyl Methacrylate (PMMA): Often known as acrylic or Plexiglas, PMMA serves in transparent applications, such as skylights or aquariums.

Advantages and Limitations

- Advantages:

- Cost-Effective: Vacuum forming generally requires lower costs compared to other molding processes, making it ideal for prototypes and short runs.

- Versatility: Capable of producing a wide range of part sizes and complexities.

- Rapid Prototyping: Allows for quick adjustments, which is especially valuable during the product design phase.

- Limitations:

- Material Thickness Variation: Due to stretching, the material can become uneven in parts.

- Limited to Thin and Medium Gauge Sheets: Vacuum forming might not be suitable for very thick plastic sheets.

- Detail Limitations: While it captures most details, extremely intricate designs or sharp undercuts might be challenging.

Challenges of Vacuum Forming Thermosetting Plastics

Thermosetting plastics have unique properties that set them apart from their thermoplastic counterparts. When it comes to vacuum forming, these properties introduce certain challenges that manufacturers and designers need to consider.

Thermal Stability and Decomposition

- No Re-melting: One of the fundamental challenges is that once thermosetting plastics cure, they don’t re-melt like thermoplastics. This can make the vacuum forming process tricky since achieving a malleable state without decomposition becomes a fine balance.

- Risk of Decomposition: When heated beyond their curing point, thermosetting plastics tend to decompose. This decomposition can release harmful gases and affect the final product’s integrity.

- Narrow Operating Window: The temperature range between making the thermoset malleable and its decomposition is often narrow, demanding precise control during the vacuum forming process.

Rigidity and Brittleness Concerns

- Limited Flexibility: Thermosetting plastics, due to their cross-linked structure, are generally more rigid. This rigidity can sometimes result in cracks or breaks during the forming process, especially around tighter curves.

- Handling Precautions: The brittleness of certain thermosetting plastics means that workers need to handle them with extra care during the vacuum forming stages to prevent unwanted damage.

Surface Finish and Detailing

- Surface Sensitivity: Thermosetting plastics can be more sensitive to surface imperfections, leading to blemishes or marks during the forming process, which can affect the final product’s aesthetic appeal.

- Detail Transfer Limitations: Due to their rigidity, thermosetting plastics might not capture extremely intricate mold details as effectively as some thermoplastics during the vacuum forming process.

- Post-Forming Modifications: Altering or improving the surface finish post-vacuum forming can be challenging. Techniques that work well for thermoplastics might not be suitable for thermosets.

Alternative Forming Methods for Thermosetting Plastics

While vacuum forming presents its own set of challenges for thermosetting plastics, the industry employs several other methods specifically tailored to the unique properties of thermosets. These alternative methods harness the strengths of thermosetting plastics, allowing for a wide array of applications.

Compression Molding

- Basics: In compression molding, manufacturers preheat a plastic material and place it into a mold cavity. They then close the mold and apply pressure, causing the material to flow and fill the mold.

- Ideal for: This method is particularly suitable for forming large, fairly intricate parts, and is a popular choice for producing automotive components, electrical housings, and more.

- Benefits: Compression molding can produce parts with fewer knit lines and less fiber-length degradation than injection molding, offering better overall strength in certain applications.

- Considerations: Precision in material quantity is crucial. Excess material can cause defects, while insufficient material might not fill the mold completely.

Injection Molding

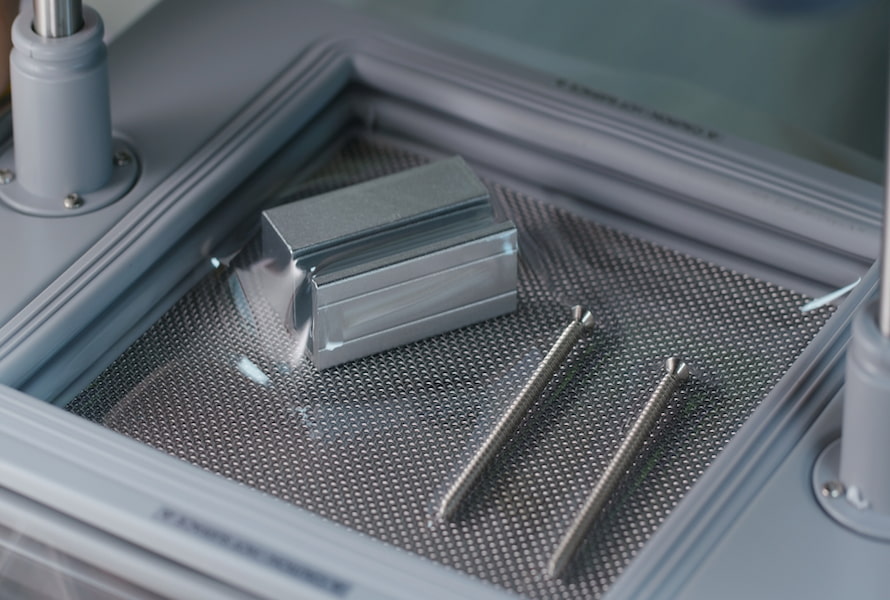

- Basics: Injection molding involves heating plastic granules to a flowable state and then injecting them under high pressure into a mold. Once cooled and solidified, the mold opens to eject the part.

- Ideal for: Suitable for mass-producing complex parts with detailed geometries. Common applications include housing for consumer electronics, automotive parts, and toys.

- Benefits: It offers high repeatability, speed, and the ability to produce intricate parts. Additionally, there’s minimal waste since any leftover material can often be reused.

- Considerations: Setting up for injection molding can be expensive due to the cost of the molds and machinery, making it more suitable for high-volume production.

Resin Transfer Molding (RTM)

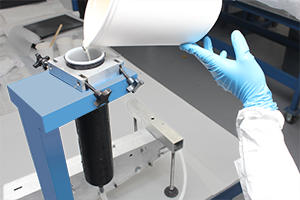

- Basics: RTM involves injecting resin into a closed mold in which the reinforcing fibers (like fiberglass) are already placed. It’s a method to produce reinforced plastic components.

- Ideal for: Producing high-quality, dimensionally accurate, composite parts. Common in automotive, aerospace, and sporting industries.

- Benefits: RTM can produce lightweight, yet strong parts with a good finish on both sides. The process can be automated, making it efficient for larger production runs.

- Considerations: The initial setup, including mold costs, can be high. Plus, careful monitoring is required to ensure consistent resin flow and prevent voids or weak spots.

Case Studies

Real-world applications and experiments often provide the most insightful perspectives on a topic. Through examining successes and failures, we can derive invaluable lessons about vacuum forming thermosets.

Successful Applications of Vacuum Forming with Thermosets

- Aerospace Components: One notable aerospace manufacturer employed vacuum forming with thermosetting plastics to create lightweight, durable interior cabin components. The selected thermoset ensured minimal off-gassing at high altitudes, a crucial factor for cabin safety.

- Medical Trays: A medical equipment provider developed sterilizable trays using thermosets. Vacuum forming allowed for precise compartments, ensuring that surgical tools remained securely in place during transportation.

- Automotive Parts: A global automotive brand integrated vacuum formed thermosetting components into their vehicle interiors. The components exhibited superior heat resistance, maintaining shape and function even when exposed to the high temperatures inside parked cars during summer.

Failures and Lessons Learned

- Consumer Electronics Housing: A startup attempted to use vacuum formed thermoset housings for their line of portable speakers. While the prototypes were promising, they encountered issues with consistency during mass production. The challenge stemmed from the narrow temperature window of their chosen thermoset, leading to frequent decomposition. The lesson? Always test a process at scale before committing to mass production.

- Food Packaging Attempt: A food packaging company aimed to replace their current thermoplastic containers with thermosetting versions, hoping for better heat resistance. Unfortunately, the chosen thermoset imparted an undesirable taste to the food. It’s a reminder that while thermosets have unique properties, they might not be suitable for all applications. Always consider the end use and potential interactions with the packaged product.