How many times can an injection mold be used?

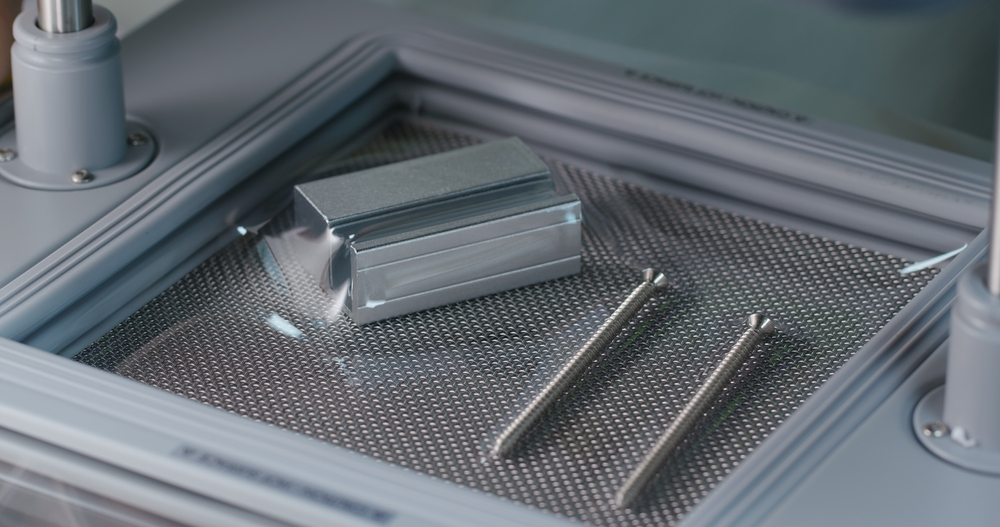

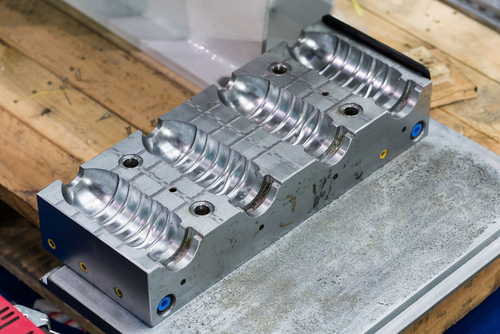

How many times can an injection mold be used:An injection mold’s usage varies from 100,000 to 1,000,000 cycles, influenced by design, material, and maintenance practices. Components of an Injection Mold Injection molding is a popular method for manufacturing plastic parts due to its efficiency and ability to produce complex geometries. The quality and consistency …