Can injection molding create complex shapes

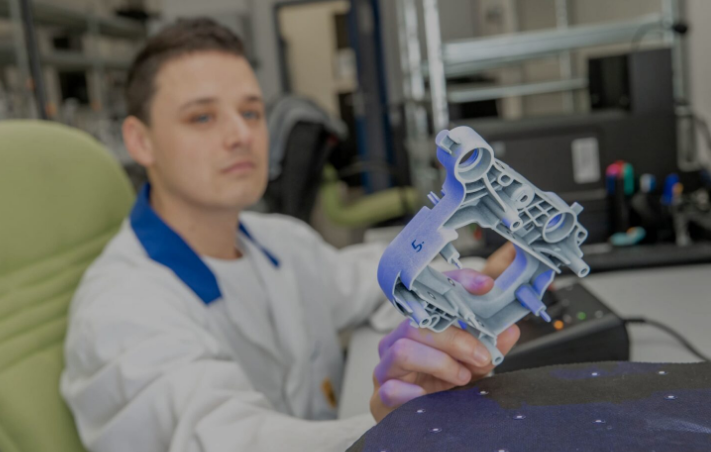

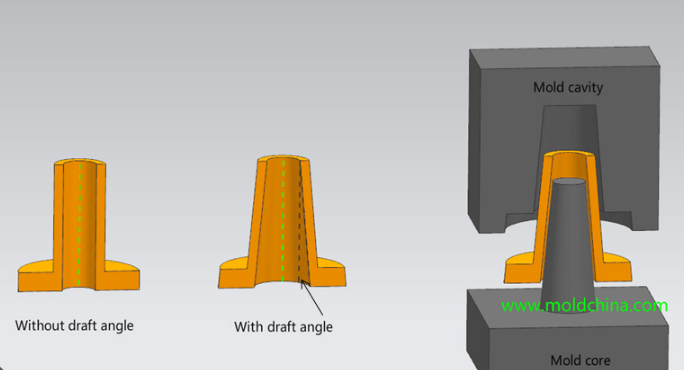

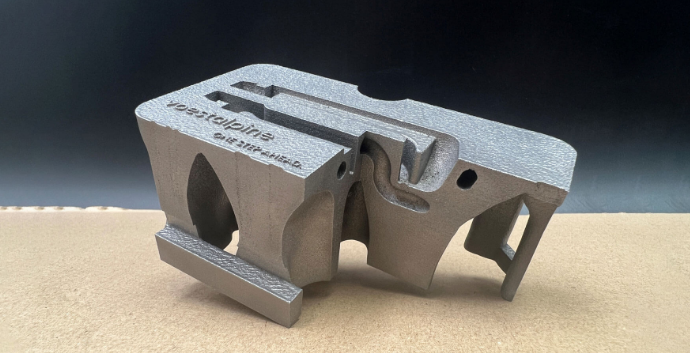

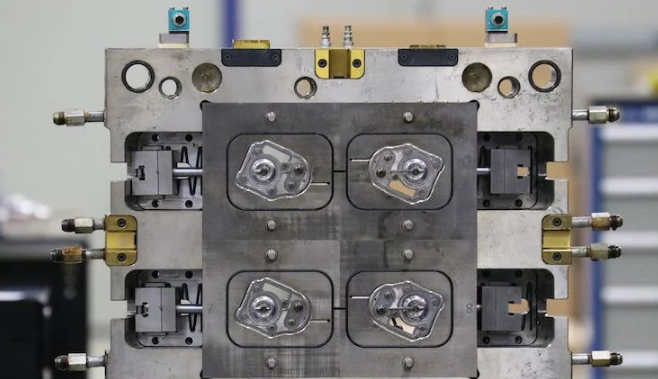

Yes, injection molding can create complex shapes, aided by advanced technologies and mold designs. Capabilities of Injection Molding in Complex Shape Production Injection molding, known for its versatility, can create parts with intricate designs. However, achieving complex shapes depends on understanding the technical limitations and material properties involved. Technical Limits in Shape Complexity Mold Design …